Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

Vibrating flat Level switch

DTA-F

STA-F

proof

construction

Non-explosion-proof

Intrinsically safe construction(i3nG5)

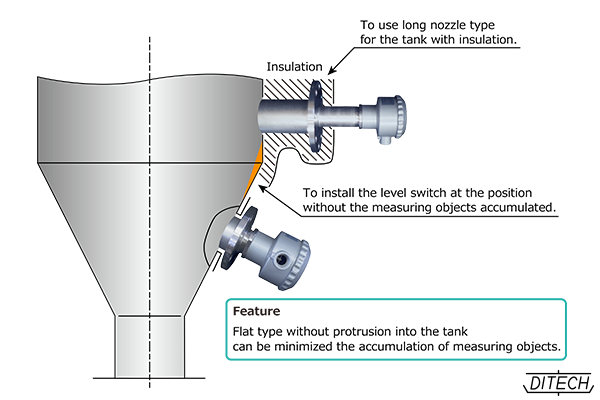

Detector consists of a single-body structure with the feature such as no protrusion into tank. These level switches are optimal for ensuring sanitary conditions, such as in the food and pharmaceutical industries.

Vibrating flat level switches offer features such as no protrusion into the tank (a feature shared with capacitive flat level switches), highly safe operation due to seal welding, and simple maintenance. These level switches are optimal for ensuring sanitary conditions, such as in the food and pharmaceutical industries.

The vibrating diaphram is welded to the disk of a cylindrical drum. The entire wetted section is fully welded. The vibration system uses a coil drive system that incorporates DITECH’s original magnetic bias. Compared with the piezoelectric element system, the vibration system is better in permissible pressure, temperature resistance and vibration efficiency, and is therefore highly sensitive.

principles

The vibrating diaphram is magnetically driven to vibrate. In a granular material or liquid, the amplitude of the vibrating diaphram’s vibration is reduced and, in an ultimate condition, stops. The diaphram’s condition is output as a contact signal.

measured

Room- and high-temperature models are available. There are two types of room-temperature models: general-purpose and granular material-only types.

|

General-purpose type Designed for a wide range of applications to measure materials such as liquids, granular materials and slurry. |

|

Granular material-only type Since this type does not detect liquids, its applications include interface detection of sediments and granular materials in a liquid. |

| Measurement system | Magnet bias system |

| Output contact | Model DTA-F: a,c,b 200V 1A 100VA (Non-inductive load) / Open collector / Thyristor / SSR Model STA-F (Model PS-7): a,c,b 200V 1A 100VA (Non-inductive load) |

| Input power | Model DTA-F: AC105V/210V 50/60Hz or DC24V Model STA-F (Model PS-7): AC105V/210V 50/60Hz |

| Power consumption | Model DTA-F: 3W Model STA-F: 4W |

| Allowable temperature | Detector: -25℃~+350℃ (Depends on the specifications) Transducer: Model PS-19F: -10℃~+50℃ Transducer: Model TR-7F: -25℃~+70℃ Power source: Model PS-7: -10℃~+50℃ Special cable: Model RG (standard type): -10℃~+60℃ Special cable: Model TEF (heat resistance use): -200℃~+260℃ |

| Allowable pressure | Detector: 1MPa (approx. 10.2kg/cm2G) (Depends on the specifications) |

| Weight | Transducer: Model PS-19F: 2.0kg Transducer: Model TR-7F: 1.75kg Power source: Model PS-7: 2.0kg |

| Size | Transducer: Model PS-19F: 154(W)×95(D)×166(H) Transducer: Model TR-7F: 154(W)×95(D)×166(H) Power source: Model PS-7: 80(W)×101(D)×210(H) (mm) |

| Installation | Detector: Flange mounting Screws mounting Ferrule IDF, etc. |

| Material | Detector: SUS304 SUS316 SUS310 SUS321 SUS329 Hastelloy, etc. Lining: PTFE Rubber, etc. Head case: Light alloy SUS304 Salt resistant paint case, etc. |

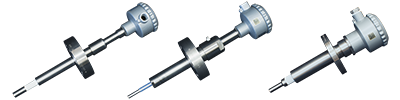

Model DTA-F-1

(Non-explosion-proof type)

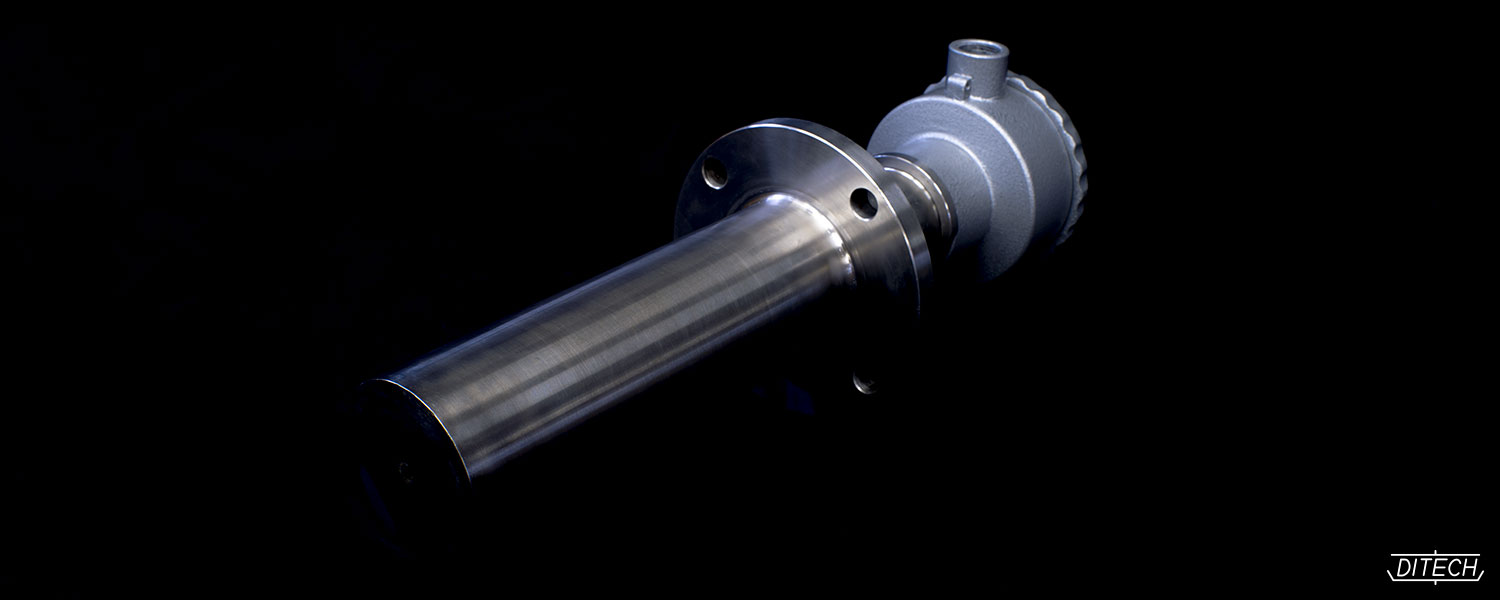

<Integrated transducer unit type>

This model is of compact type in which both detector unit and transducer (relay power source) are integrated.

Model DTA-F-2

(Non-explosion-proof type)

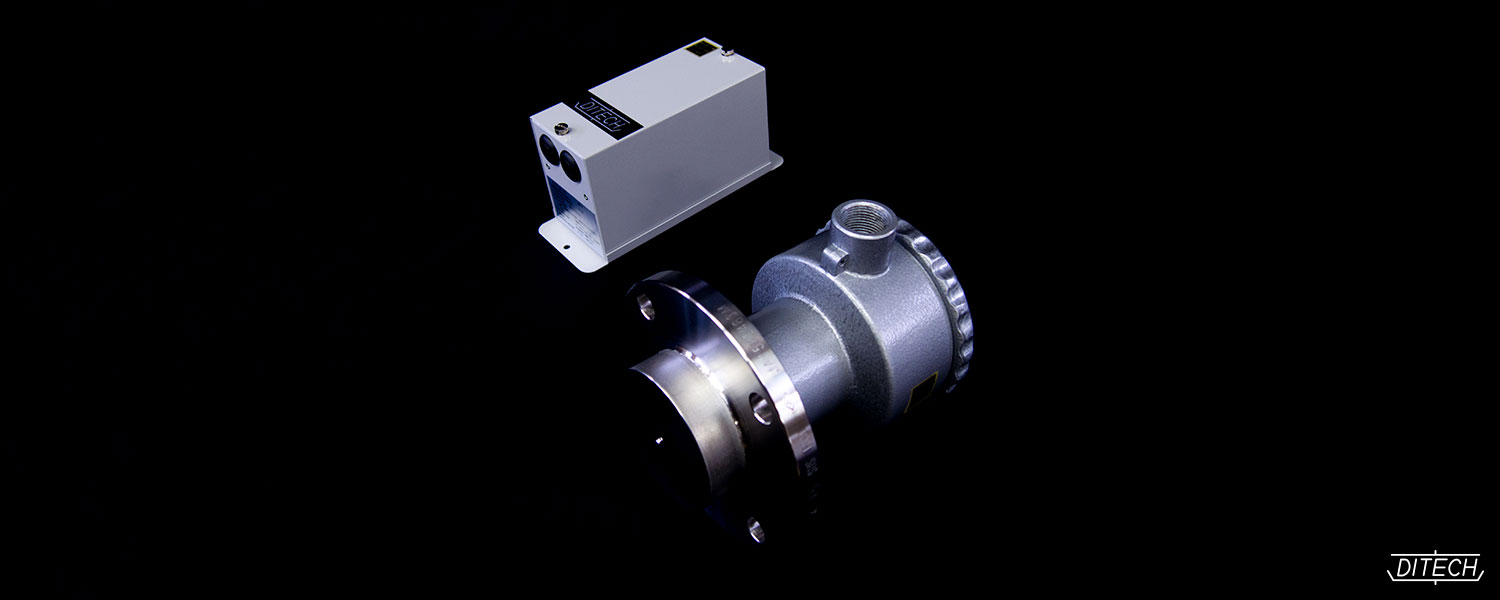

<Separated transducer type>

This model is composed of both detector unit, transducer (relay power source) and special cable. Transducer may be installed far from the area exposed to Heat, Steam, Vibration, Powder or Gas. This has the same characteristics as those of Integrated transducer unit type as to performance.

Model STA-F-1

(Intrinsically safe construction / i3nG5)

<Integrated transducer unit type>

This model is composed of both detector unit with self-contained transducer and relay power source (Model PS-7). The transducer contained in the detector head requires no special cable. For this reason, the dangerous area may be kept away unlimitedly from the safe area. As to performance, this model has the same characteristics as those of Model DTA-F.

Model STA-F-2

(Intrinsically safe construction / i3nG5)

<Separated transducer type>

This model is composed of detector unit, transducer, relay power source (Model PS-7) and special cable. The transducer may be installed far from the area exposed to Heat, Steam, Vibration, Powder or Gas. This model has the same characteristics as those of Model DTA-F and the equivalent performance to those of Integrated transducer unit type.

DITECH,LTD.

DITECH,LTD.