Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

General-purpose

Vibrating Level switch

DTA-G

STA-G

proof

construction

Non-explosion-proof

Intrinsically safe construction(i3nG5)

General-purpose vibrating level switch at reasonable price and in short delivery

The mounting (connection) and length (any length between 250 mm and 2,000 mm) of this level switch can be fully designed according to the user’s specifications. Moreover, this model can be ready for shipment to meet a short delivery schedule (within 10 days after receiving an order).

General-purpose capacitive type level switches are also available.

These are the switch in which the detection by the human sense of touch is applied to the level switch, enhancing its reliabilities by taking advantage of the features that only the human sense of touch possesses. General-purpose vibrating level switch is the one that can well respond to the demand in the market for instrumentation of high reliabilities ever getting higher, by taking full advantage of the latest development in electronic technologies.

principles

Under this system, the tip of the detecting element, which consists of a single metal probe, is delicately vibrated. The detecting element's vibration control characteristics vary according to the substance being measured and the resulting signal forms the basis of an accurate level measurement. By adjusting the strength and frequency of the vibration, the system can be employed for measurement of a wide variety of substances. The operation is based on electrostrictive mechanisms.

-

Wide and flexible measurement application range encompassing powders, granular materials and solutions.

-

Vibrating level switches with a straight-rod probe can be installed through a 25A nozzle.

-

High stability and long operating life thanks to a delicate vibration system that doesn’t expose the detecting element to fatigue.

-

Our mechanical level switches (Model DTA-G and STA-G) with characteristic vibration (self-excited vibration) can prevent from forming the rat hole while general mechanical level switches have disadvantage of easily generating the rat hole.

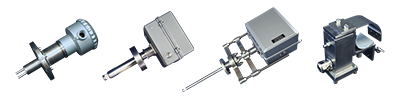

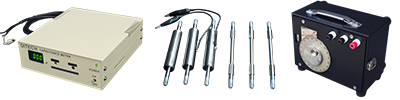

| Measurement system | Vibrating system (Electrostrictive mechanisms) |

| Output signal | Model DTA-G: a, c, b 200V 1A 100VA (Non-inductive load) Model STA-G (Model PS-7): a, c, b 200V 1A 100VA (Non-inductive load) |

| Input power | Model DTA-G: AC105V/210V 50/60Hz or DC24V Model STA-G (Model PS-7): AC105V/210V 50/60Hz |

| Power consumption | Model DTA: 5W Model STA: 4W |

| Vibration frequency | 100Hz~10KHz (Depends on the specifications) |

| Allowable temperature | Detector: -20℃~+70℃ (Depends on the specifications) Transducer: Model PS-19G: -10℃~+50℃ Transducer: Model TR-7G: -25℃~+70℃ Power source: Model PS-7: -10℃~+50℃ Special cable: Model RG (standard type): -10℃~+60℃ Special cable: Model TEF (heat resistance use): -200℃~+260℃ |

| Allowable load | Detector: Up to 250m: 1300kg/m2 Up to 1m: 700kg/m2 Up to 2m: 200kg/m2 |

| Allowable pressure | Detector: 1MPa (approx. 10.2kg/cm2G) |

| Weight | Transducer: Model PS-19G: 2.0kg Transducer: Model TR-7G: 1.75kg Power source: Model PS-7: 2.0kg |

| Size | Transducer: Model PS-19G: 154(W)×95(D)×166(H) Transducer: Model TR-7G: 154(W)×95(D)×166(H) Power source: Model PS-7: 80(W)×101(D)×210(H) (mm) |

| Installation | Detector: Flange mounting Screws mounting, etc. |

| Material | Detector: SUS304, etc. Head case: Light alloy Salt resistant paint case |

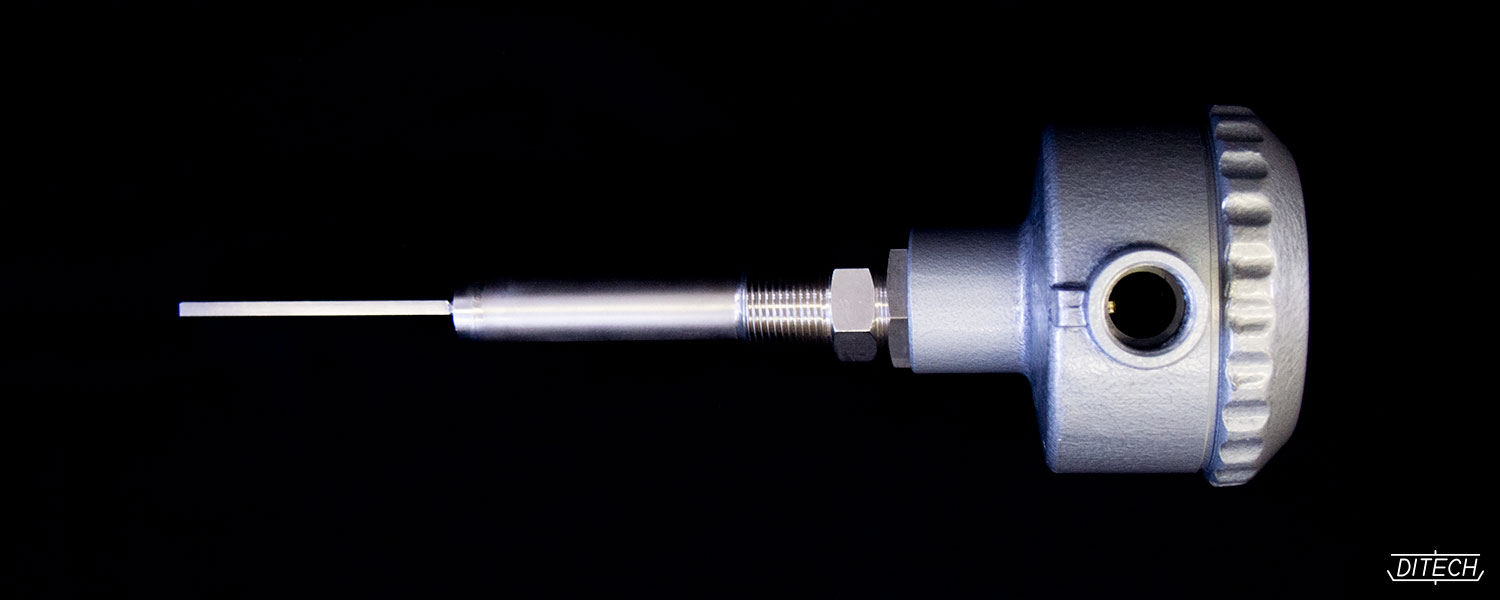

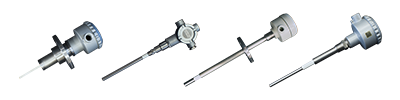

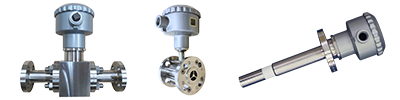

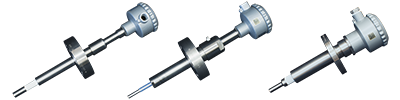

Model DTA-G-1

(Non-explosion-proof type)

<Integrated transducer unit type>

This model is of compact type in which both detector unit and transducer (relay power source) are integrated.

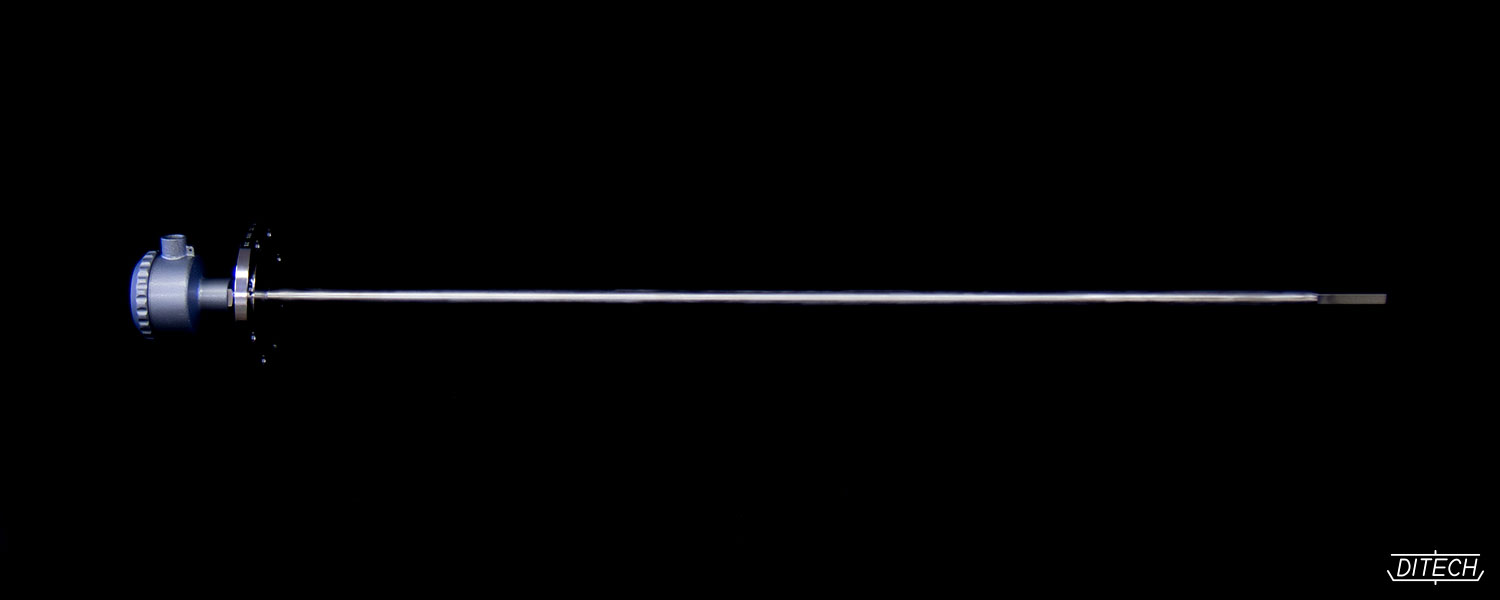

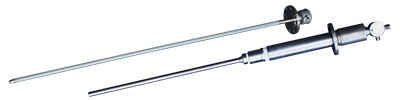

Model DTA-G-2

(Non-explosion-proof type)

<Separated transducer type>

This model is composed of both detector unit, transducer (relay power source) and special cable. Transducer may be installed far from the area exposed to Heat, Steam, Vibration, Powder or Gas. This has the same characteristics as those of Integrated transducer unit type as to performance.

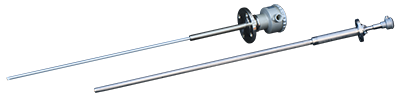

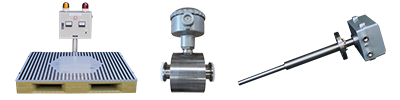

Model STA-G-1

(Intrinsically safe construction / i3nG5)

<Integrated transducer unit type>

This model is composed of both detector unit with self-contained transducer and relay power source (Model PS-7). The transducer contained in the detector head requires no special cable. For this reason, the dangerous area may be kept away unlimitedly from the safe area. As to performance, this model has the same characteristics as those of Model DTA-G.

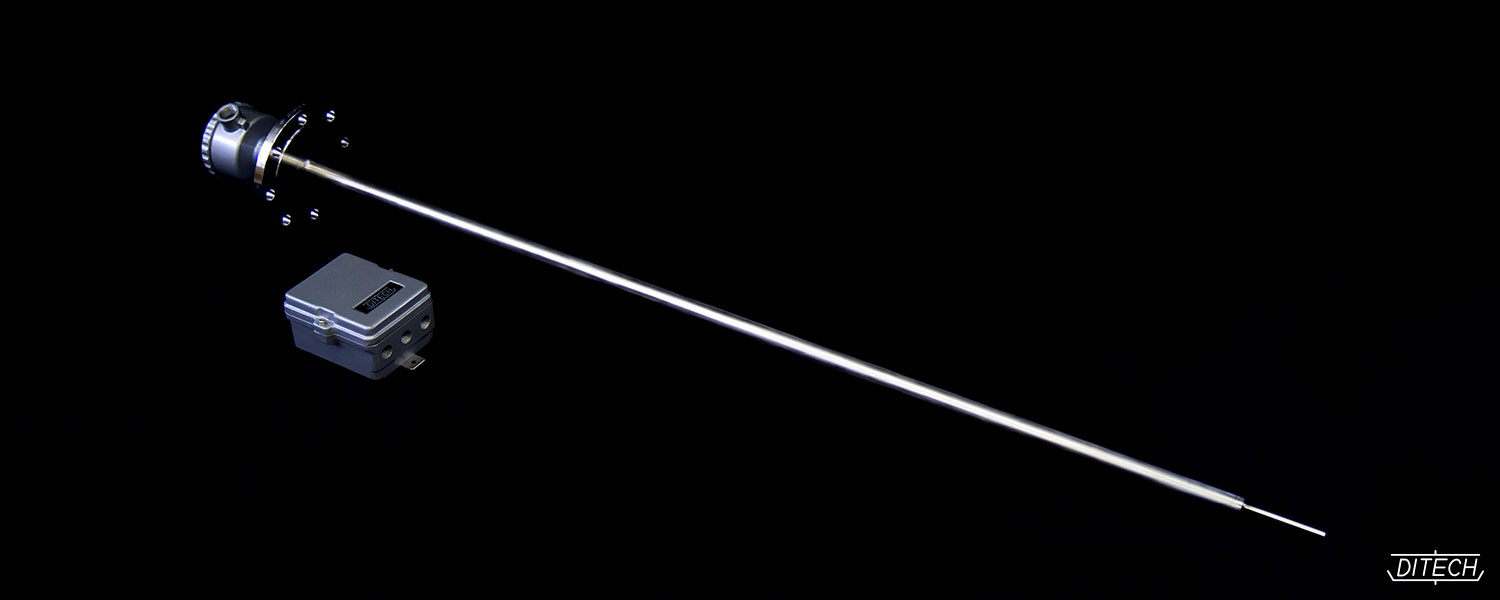

Model STA-G-2

(Intrinsically safe construction / i3nG5)

<Separated transducer type>

This model is composed of detector unit, transducer, relay power source (Model PS-7) and special cable. The transducer may be installed far from the area exposed to Heat, Steam, Vibration, Powder or Gas. This model has the same characteristics as those of Model DTA-G and the equivalent performance to those of Integrated transducer unit type.

DITECH,LTD.

DITECH,LTD.