Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

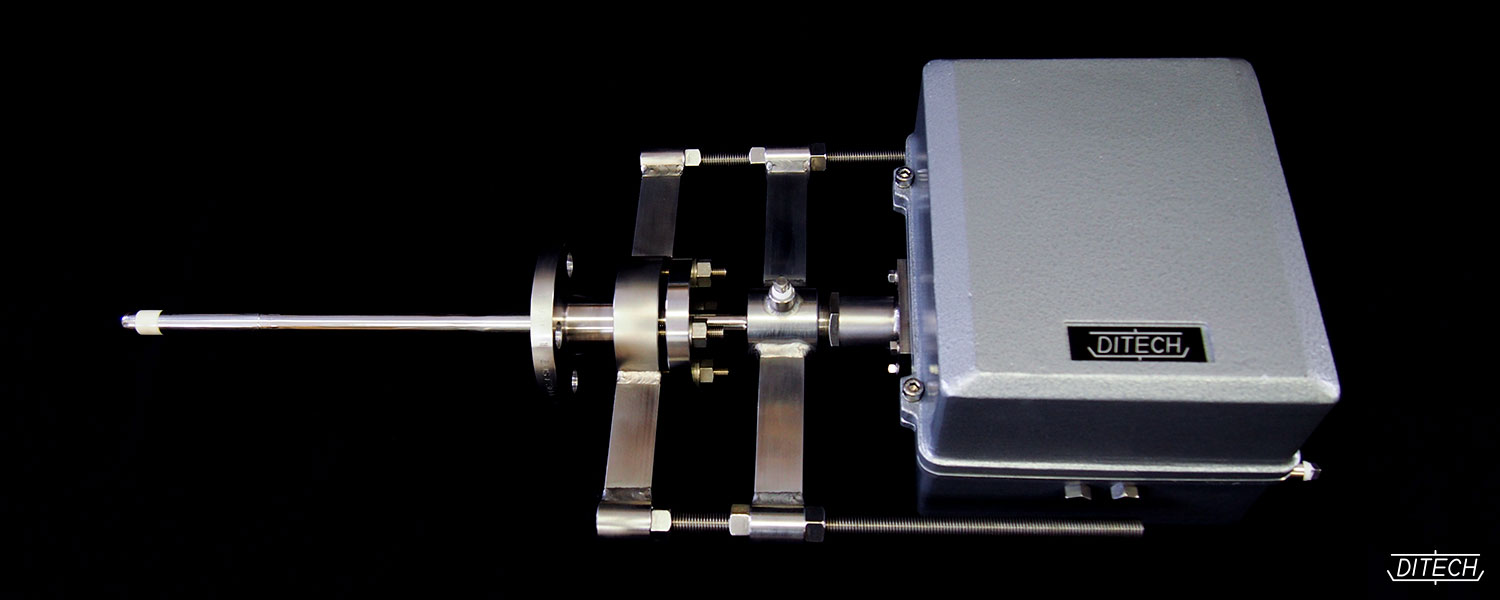

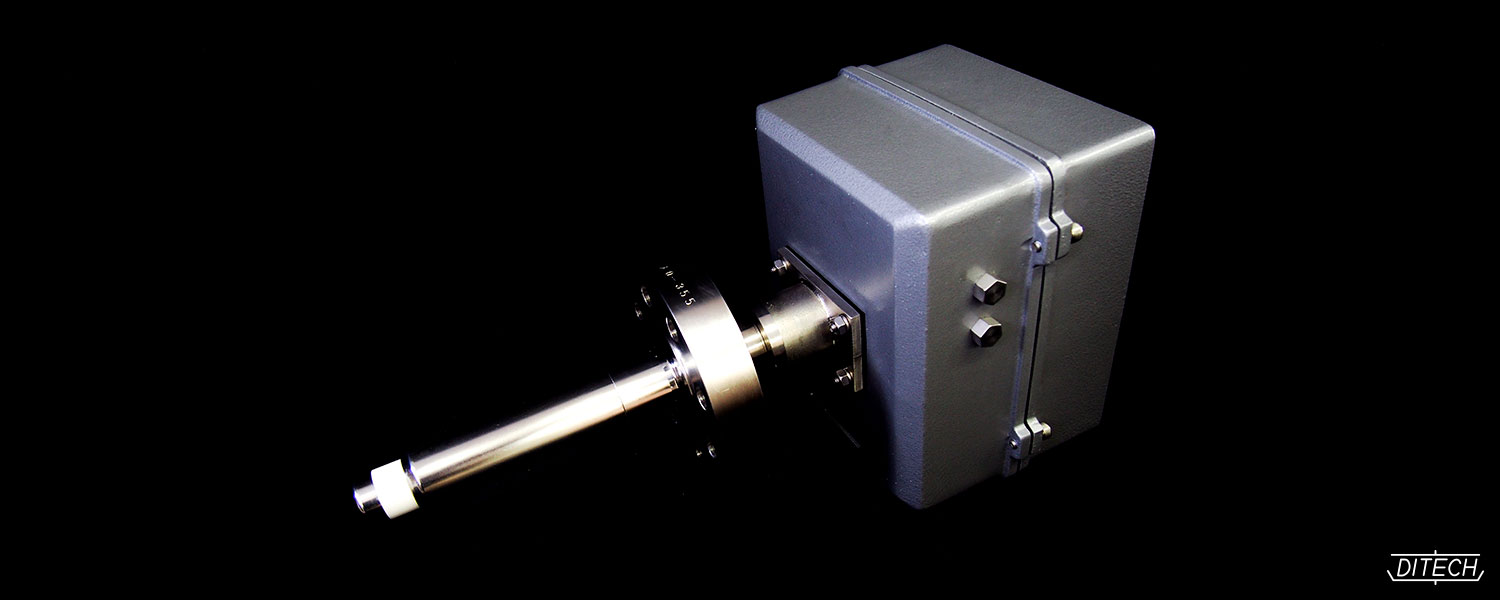

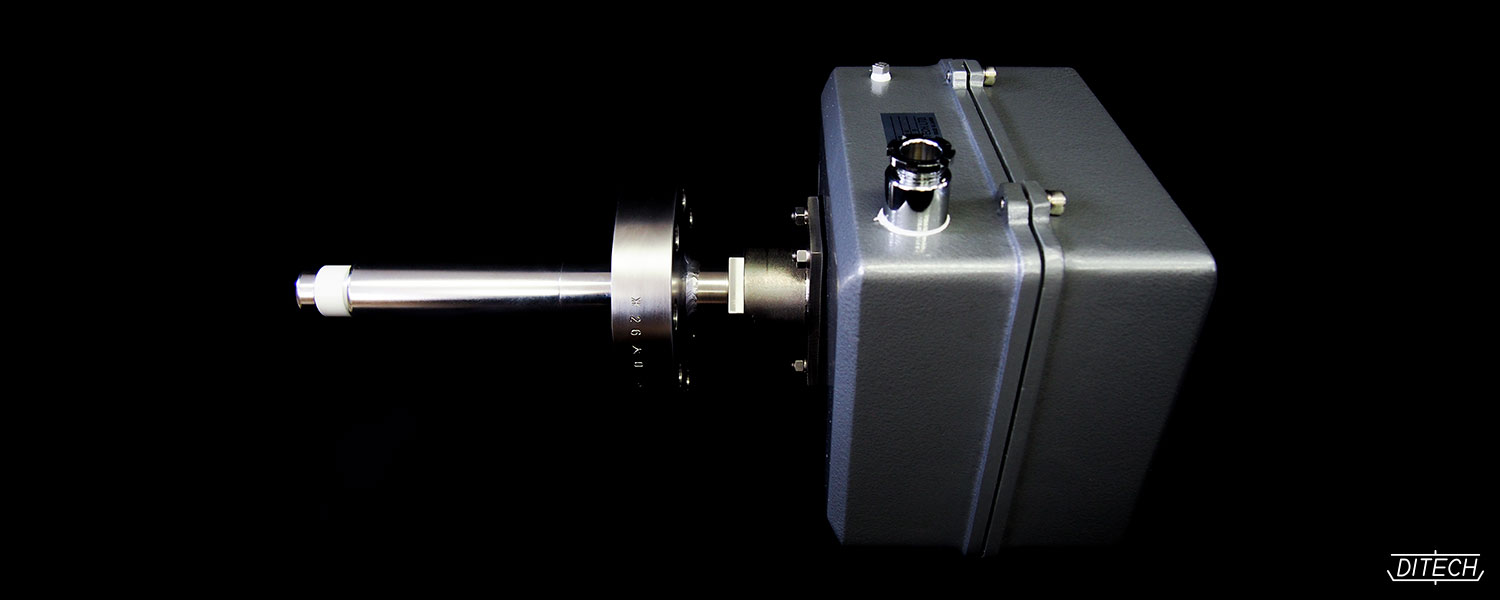

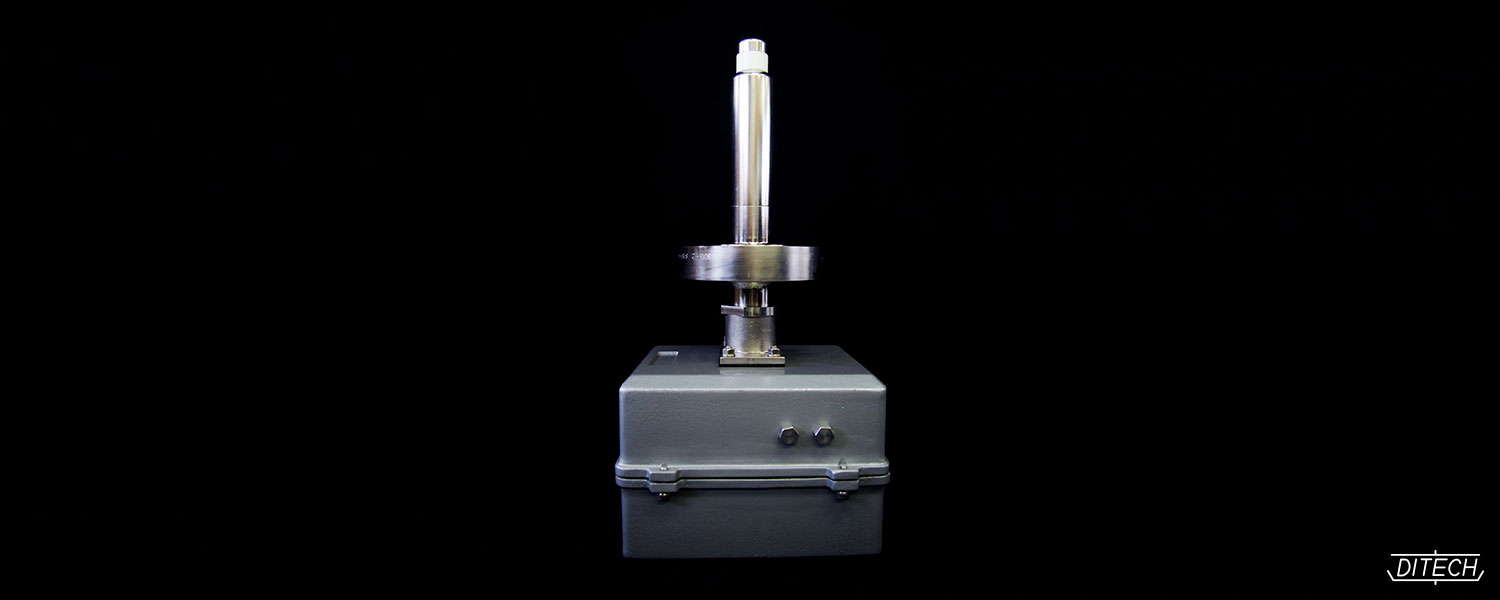

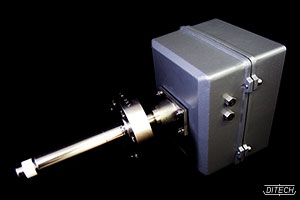

Electrostatic ammeter

S-22

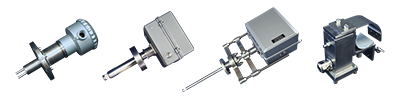

proof

construction

Intrinsically safe construction(i2G4)

to be

measured

Electrostatic currents of an electrically charged powder or granular material in manufacturing processes

This device is designed to measure, in a powder and/or granular material manufacturing process, extremely small electrostatic currents generated by a charged powder or granular material. The electrostatic ammeter allows manufacturing processes to achieve stable operation by measuring the current generated in a reactor and using the measurement as an indicator.

Electrostatic voltmeter for electrostatic potential of an electrically charged powder or granular material in manufacturing processes is also available.

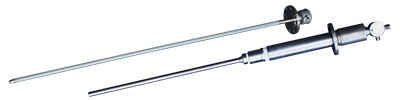

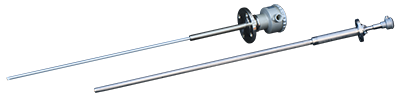

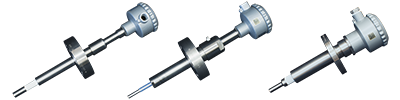

Install the collecting electrode in the target process line. Guide the electrostatic current to a location outside the target process line via a lead wire sealed from the outside air. Connect this lead wire first to a resistor of known high resistance and then to a precise resistor of known resistance. A voltage proportional to the electrostatic current is generated across the precise resistor. By measuring both the electrostatic voltage and current, it is possible to surmise the conditions in the target process line, using the relationship Q = CV. The state of reactions in a reactor is represented by changes in V, since C is virtually constant in reactors. In piping, V is virtually constant and changes in C are proportional to the density of the passing gas (granular materials mixing ratio).

Insulate, seal and extend the lead wire of the collecting electrode protruding into the target process line up to the terminal box outside the target process line. From the terminal box, lay a cable up to a non-hazardous area and connect to the input of an isolator via a Zener barrier.

| Measurement range | ±100nA ±1μA ±10μA |

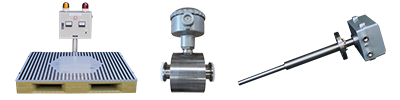

| Output signal | DC 12mA±8mA (4~20mA) |

| Input power | AC100V 50/60Hz or DC24V |

| Power consumption | 12W |

| Dielectric strength | 20KV 50KV, etc. (Depends on the specifications) |

| Allowable temperature | Detector: 0℃~+150℃ (Depends on the specifications) |

| Allowable load | Detector: 1000㎏ Concentrated at detection tip (Depends on the specifications) |

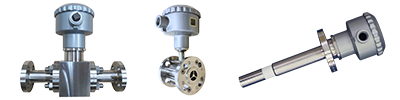

| Allowable pressure | Detector: 2Mpa (approx. 20.4kg/cm2G) (Depends on the specifications) |

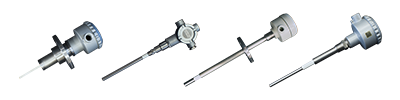

| Surface treatment | Detector: Buff Electrolytic polishing, etc. |

| Installation | Detector: Flange mounting, etc. |

| Material | Detector: SUS304 SUS316 PTFE Ceramic, etc. Head case: Light alloy Pressure resistant SUS304 case Salt resistant paint case, etc |

DITECH,LTD.

DITECH,LTD.