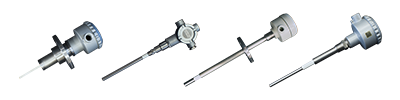

Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

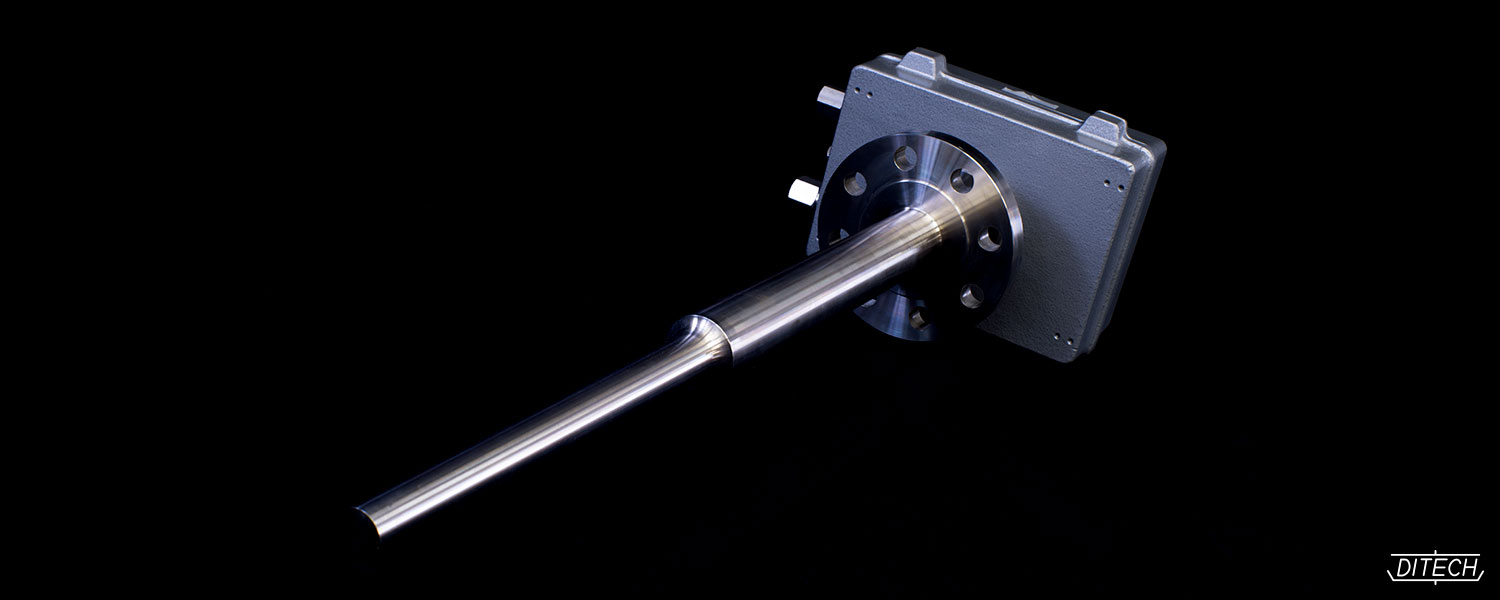

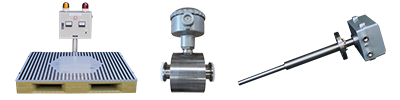

Lump detector

D-S

LD-11

proof

construction

Non-explosion-proof

Intrinsically safe construction(i2BT4)

system

Strain system

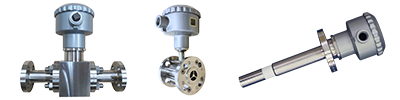

Fluidized powder in a vessel in a manufacturing process may form lumps, which may move in the vessel due to the rotary flow of gas. This lump detector is used in such manufacturing processes to measure the size of lumps according to the magnitude of the impact caused by a lump colliding with the sensor, and also to determine lump formation rate from the collision frequency.

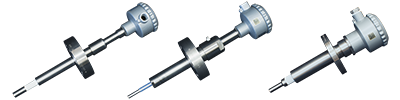

The high-precision strain gauge provided in the detector constructed to the optimal load design produces measurements, making a distinction possible between vertical and horizontal directions. Sound and reliable design and manufacturing technologies are combined in the device, since it must be pressure-resistant and capable of detecting repeated strains.

principles

In a gas-phase polyethylene plant, lumps formed in a fluidized powder move in a vessel due to the rotary flow of the gas. When a lump hits the sensor, a strain results from the impact force. Since the strain is proportional to the impact force, it is possible to determine the size of the lump. Measuring this phenomenon enables the operator to know, in advance, the likeliness of the powder in a tank to clog the discharge port and therefore ensure stable plant operation.

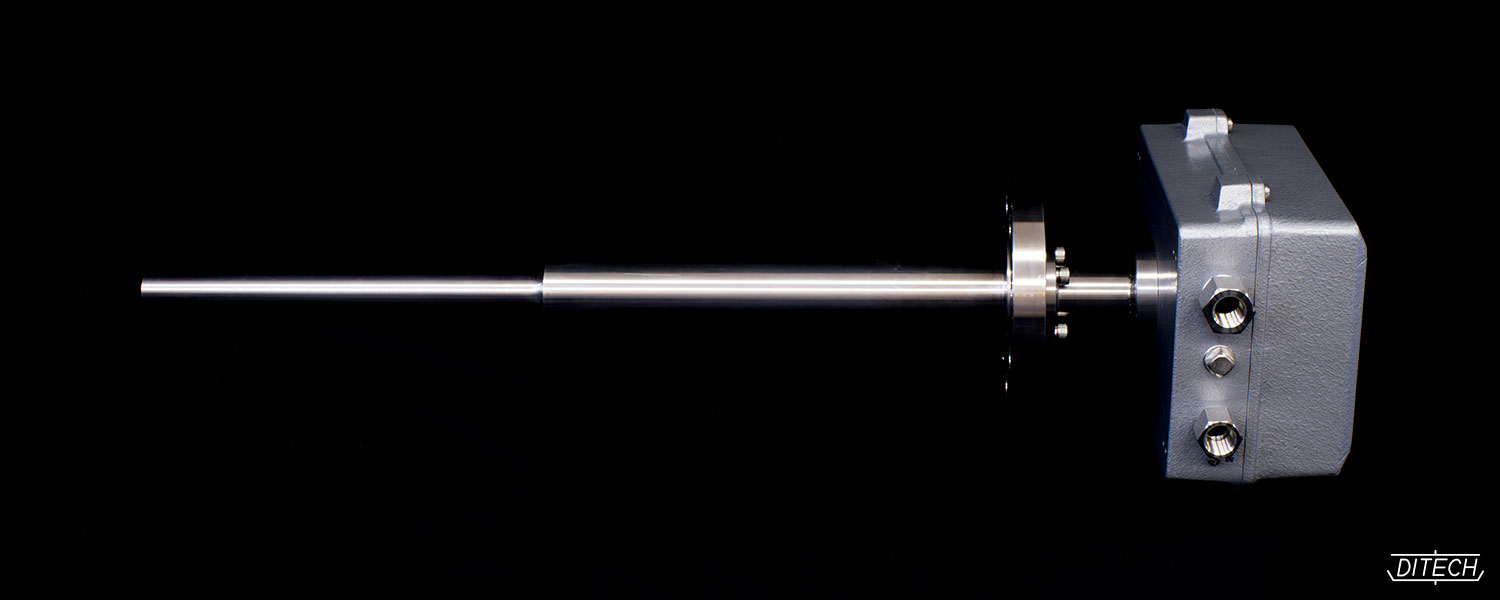

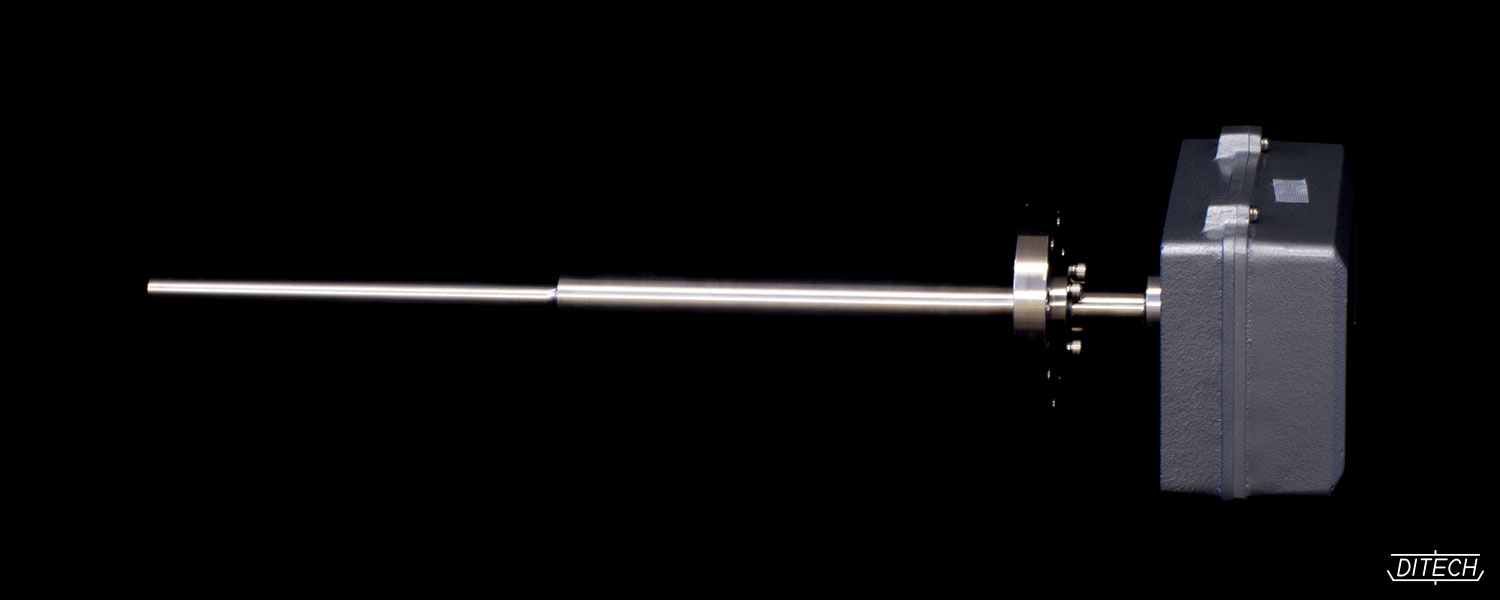

When a lump hits the hollow rod protruding in a vessel, the strain in the hollow rod resulting from the impact is transmitted to the strain gauge in the rod and detected as a change in electrical resistance. The strain gauge consists of a set of x-axis and y-axis elements, which generate respective signals.

| Measurement range | 0~30kg or 0~60kg (According to user's specifications) |

| Output signal | DC4~20mA DC1~5V ※ One of the above signal |

| Input power | AC108V~132V 50/60Hz |

| Allowable temperature | Detector: -20℃~+120℃ (According to user's specifications) Transducer: Model BB-11: -20℃~+60℃ Transducer: Model BB-12: -20℃~+60℃ Bridge box: -25℃~+70℃ Indicator: -10℃~+50℃ Safety maintaining device: -20℃~+60℃ |

| Allowable load | According to user's specifications |

| Allowable pressure | According to user's specifications |

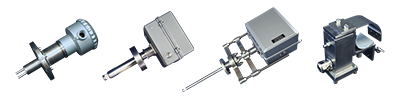

| Weight | Transducer: 0.35kg Indicator: 1.1kg Bridge box: 4.2kg Safety maintaining device: 0.15kg |

| Size | Transducer: 49(W)×122(D)×79(H) Indicator: 49(W)×262.5(D)×128.5(H) Bridge box: 216(W)×125(D)×259(H) Safety maintaining device: 12.5(W)×110(D)×115(H) (mm) |

| Installation | Detector: Flange mounting, etc. |

| Material | Detector: SUS304 SUS316 SUS316L, etc. Head case: Light alloy SUS304 Salt resistant paint case, etc. |

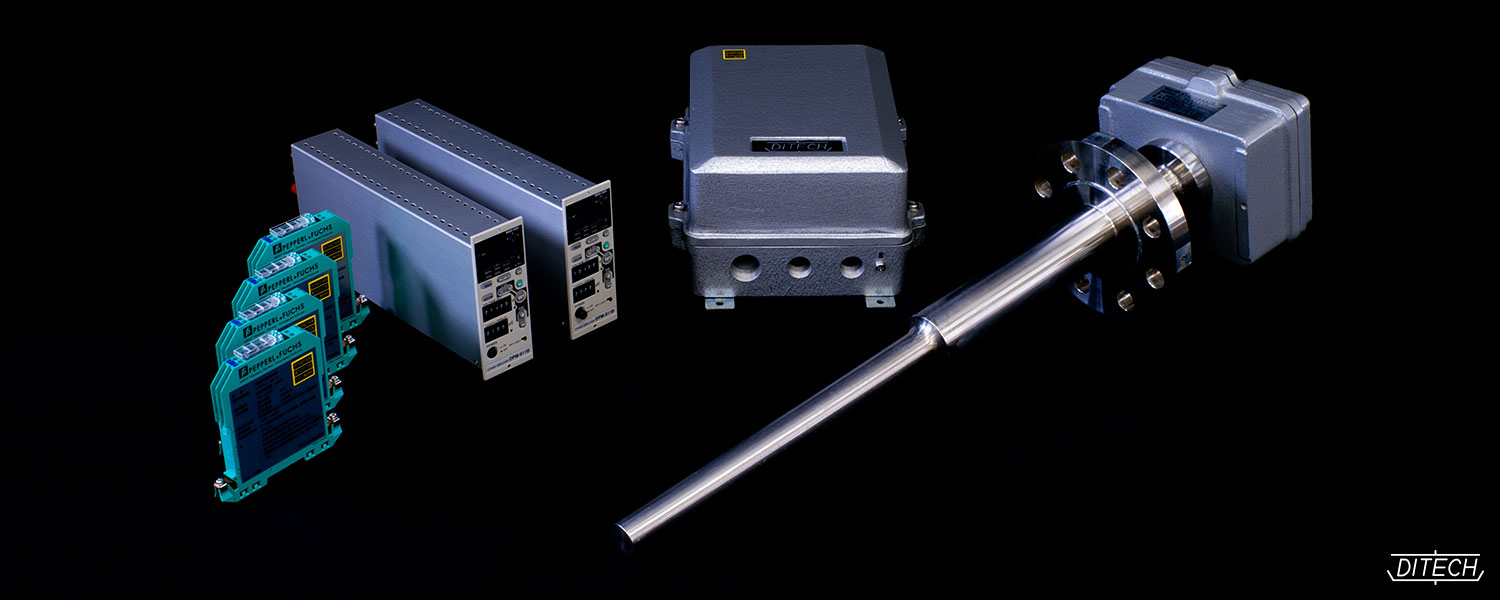

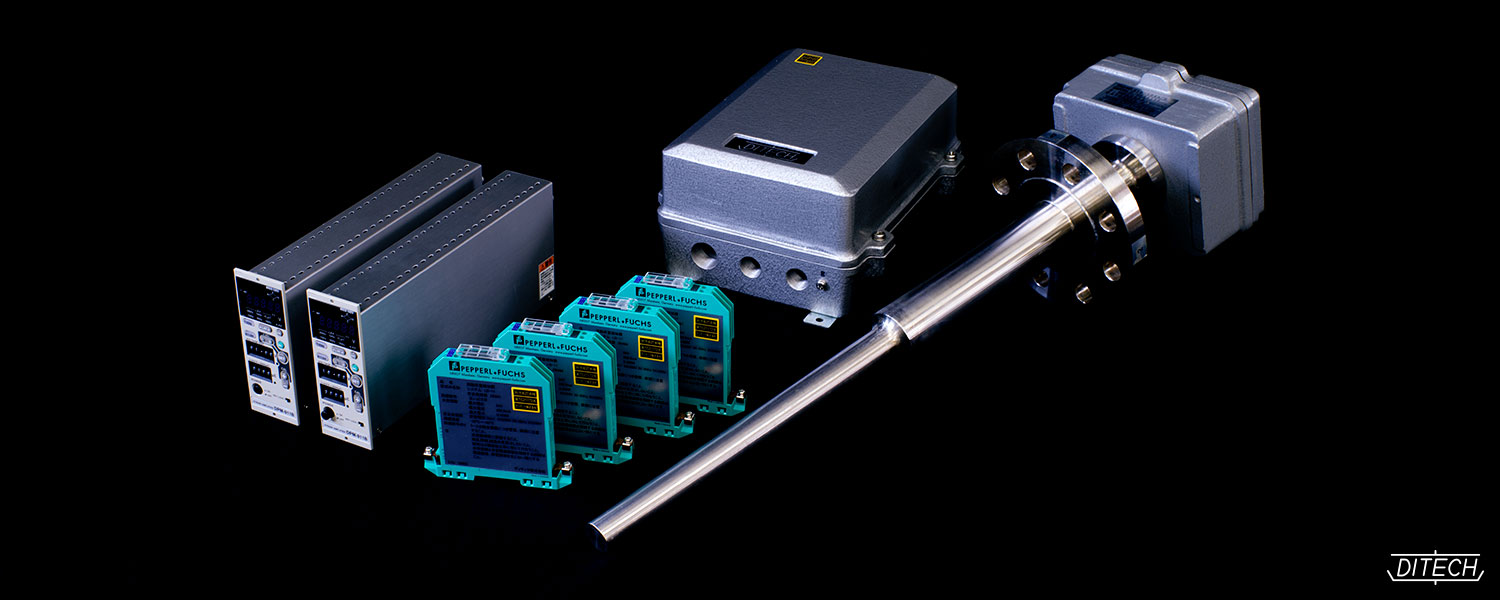

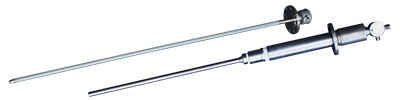

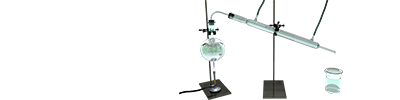

Model D-S

(Non-explosion-proof type)

<Separated transducer type>

This model is composed of detector, transducer and 2 indicators.

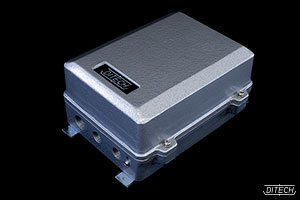

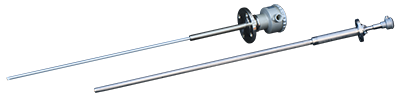

Model LD-11

(Intrinsically safe construction / i2BT4)

<Totally separated detector unit type>

This model is composed of detector unit, transducer, 4 safety maintaining devices (safety barrier), and 2 indicators.

DITECH,LTD.

DITECH,LTD.