Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

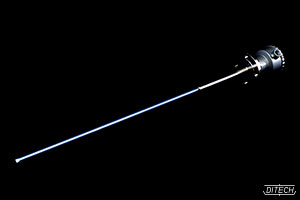

Capacitive interface

Level transmitter

QBS-IF

NSB-IF

proof

construction

Non-explosion-proof

Intrinsically safe construction(i3nG5)

measured

Boundary surface of two types of liquid

Loss of electrical capacitance during measurement is an intrinsic problem that plagues conventional electrostatic capacitance. To overcome it, DITECH's Non-induction Electrostatic Capacitance Series employs innovative technology to prevent capacity losses during the measurement process both within the meter circuitry and along the non-induction extension cable between the electrodes. Thanks to this technology, these devices offer unprecedented accuracy and stability. This instrument has been designed based on a totally new measurement concept and advanced electronics to exhibit high performance as an interface level transmitter for applications in which either the overlying or underlying fluid have relative permittivity of 5 or less.

DITECH has a wealth of experience in conducting elaborate testing of samples and plenty of expertise in dealing with water and other liquids of various properties. We offer optimal products for the object you would like to be measured.

principles

Every material has intrinsic electrical characteristics such as permittivity and conductivity. Boundary surface of two types of liquid can be detected by measuring the liquid having higher permittivity out of two types of liquid. This transmitter detects electrostatic capacitance changes generated by the rise or fall of the level of the measured substance in the tank, and then converts these changes into an integrated signal. A variety of meters and detectors are available according to the measurement condition.

-

Non-induction system designed to be totally unaffected by capacitance losses.

-

Totally electronic system with no moving parts ensures a long working life.

-

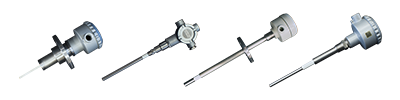

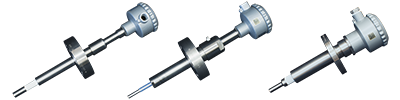

An increased degree of design freedom make it possible to adjust the electrode shape to match the measurement location conditions.

(Straight-rod probe type, Wire type, etc.) -

Solid body construction designed for long-term durability and easy maintenance.

-

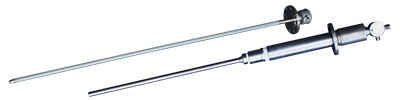

Detector and transducer can be separately installed without effecting the device's operating performance.

| Measurement range | Min. range 0~100mm , Max. range 0~10m (Any other range are possible) |

| Output signal | DC4~20mA DC1~5V ※ One of the above signal |

| Input power | Model QBS-IF (Model PS-0IF): AC105V/210V 50/60Hz or DC24V Model NSB-IF (Model PS-2): AC105V/210V 50/60Hz |

| Power consumption | 10W |

| Linearity | ±0.5% FS |

| Allowable electrode conductance(G) |

3μS |

| Allowable electrode distribution capacity(Co) |

0~180pF or 0~500pF |

| Allowable temperature | Detector: -200℃~+1100℃ (Depends on the specifications) Transducer: Model PS-0IF: -10℃~+50℃ Transducer: Model TR-2IF: -25℃~+70℃ Power source: Model PS-2: -10℃~+50℃ Special cable: Model DSC-15 (high accuracy use): -10℃~+60℃ Special cable: Model DSC-05 (small size): -10℃~+60℃ Special cable: Model DSC-13 (heat resistance use): -50℃~+200℃ |

| Allowable pressure | Detector: 100MPa (approx. 1020kg/cm2G) (Depends on the specifications) |

| Weight | Transducer: Model PS-0IF: 5.5kg Transducer: Model TR-2IF: 4.3kg Power source: Model PS-2: 7.6kg |

| Size | Transducer: Model PS-0IF: 216(W)×125(D)×259(H) Transducer: Model TR-2IF: 200(W)×149(D)×220(H) Power source: Model PS-2: 250(W)×145(D)×275(H) (mm) |

| Installation | Detector: Flange mounting Screws mounting IDF Grayloc connector Ferrule Ring joint Lens Aminco Non-standard flange, etc. |

| Material | Detector: SUS304 SUS316 SUS316L Hastelloy Titanium Tantalum Nickel PTFE Ceramic, etc. Lining: PTFE Glass Rubber, etc. Head case: Light alloy SUS304 Salt resistant paint case, etc. |

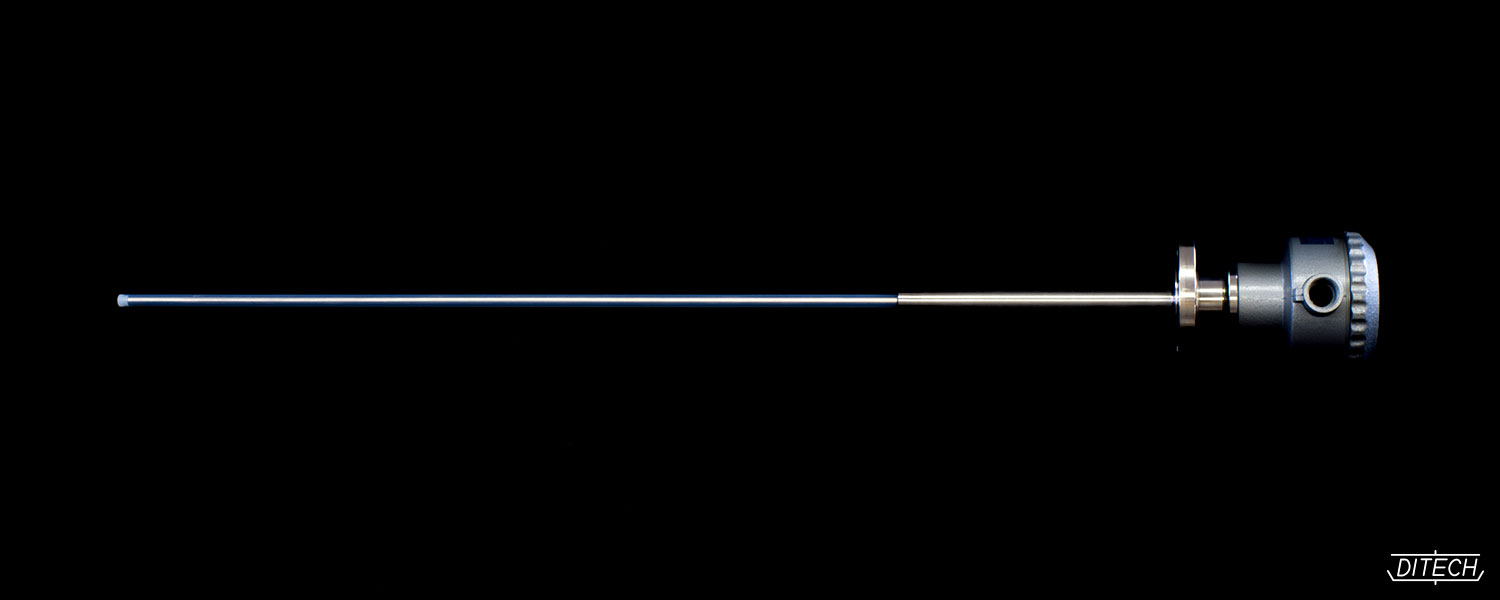

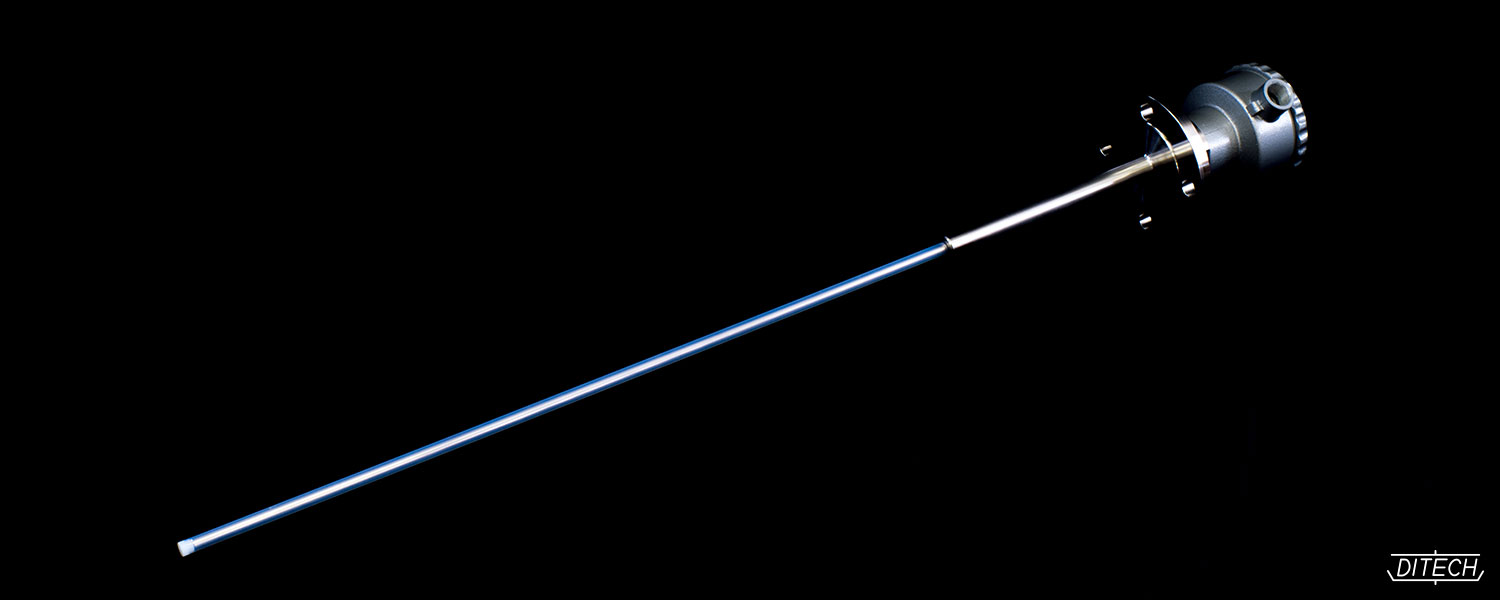

Model QBS-IF

(Non-explosion-proof type)

<Separated transducer type>

This model is composed of detector unit, transducer and special cable.

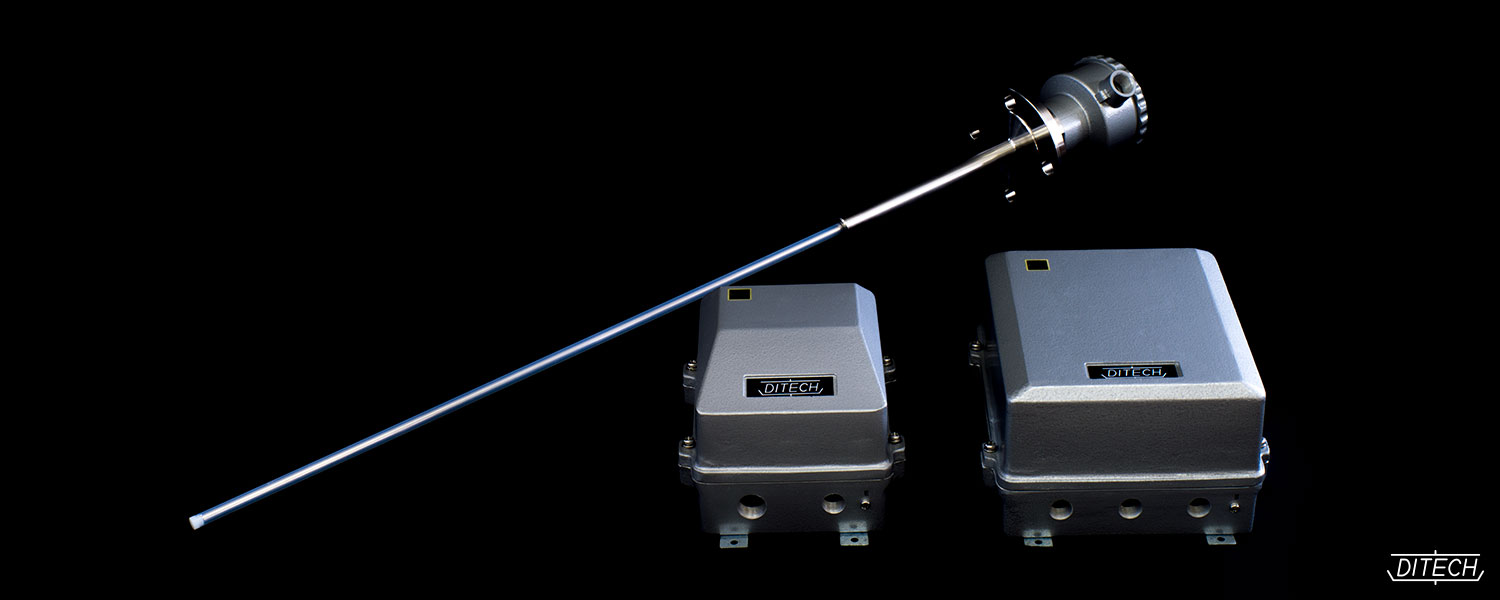

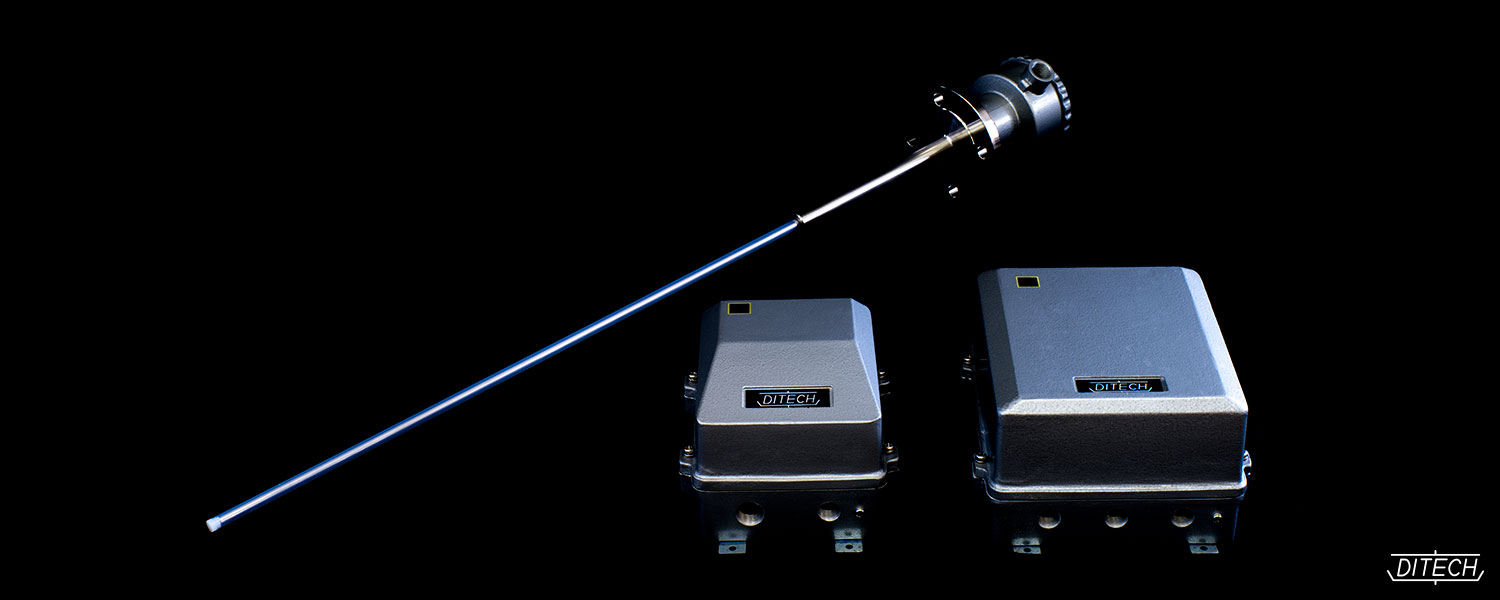

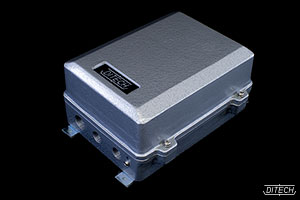

Model NSB-IF

(Intrinsically safe construction / i3nG5)

<Totally separated detector unit type>

This model is composed of detector unit, transducer, relay power source and special cable that is 4 core control cable. As the transducer is designed to be installed in a dangerous area, the special cable can be made short enough to minimize picked-up noises, thus permitting a stable performance to be obtainable. As to performance, this model has the same characteristics as those of Model QBS-IF.

DITECH,LTD.

DITECH,LTD.