Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

Self-balancing interface

Level transmitter

system

Impedance system

NQC-10

Non-explosion-proof type

NSC-10

Intrinsically safe construction

system

Vibrating system

Float system

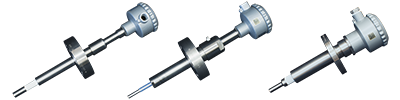

NQC-V

Non-explosion-proof

NSC-F

Non-explosion-proof

The self-balancing interface level transmitter series comprises interface level transmitters that feature a combination of various sensors that exhibit specific performance and a self-balancing mechanism. Selecting optimal sensors suitable for specific measurement conditions enables level measurements in numerous applications which previously were difficult to measure. The key is to use the sensor that operates on the most suitable detecting principle for the target substance.

This transmitters (Model NQC and NSC) are designed to convert the interface level of powders or granular materials in tank into the unified signal by a self-balancing mechanism.

Measurement span can be set up at certain point from 0~0.5m to 0~10m. (Changing the set point can be done by us after installation.) Support may be provided to reinforce in case of in case of heavier load on seal piping. Drive parts as well as electronic circuit are robust design for long term use and durable under severe condition.

principles

Every material has intrinsic electrical characteristics such as permittivity and conductivity.

If two materials that form an interface to be measured differ in electrical characteristics, it is possible to measure the interface.

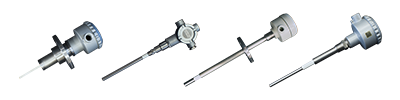

A sealed pipe is attached inside the tank. A small moving probe is inserted in the pipe.

The interface of the substance to be measured is detected across the wall of the sealed pipe.

The self-balancing capability is provided by a servomechanism. The location of the interface is converted into a standardized signal for transmission.

This system uses differences in viscosity value. By allowing the sensor to follow the interface level, it accurately converts the level into a standardized signal for transmission. It is free of errors resulting from changes in moisture content, temperature, humidity, permittivity, color tone and the like of the substance to be measured. The vibrating level transmitter is suitable for the activated sludge or the sand particle to measure the interface between the sediment and the overlying water.

A float perforated the seal pipe is placed on the surface of the liquid. A small moving probe is inserted in the seal pipe. The interface of the substance to be measured is detected across the wall of the seal pipe. The self-balancing capability is provided by a servomechanism. The location of the interface is converted into a standardized signal for transmission.

-

Totally new measurement concept enables level measurements in numerous applications. Possible to measure powder, granule, concentrated slurry, industrial waste water and high electro conductive and viscous object such as night soil.

Measure with high accuracy under severe condition that is stuck and deposited in-process and online. -

Short probe together with upper and lower compensating electrodes enables high sensitivity unaffected by adhesion of foreign substances to top plate or bottom plate.

-

Self-balancing level transmitter provided by servomechanism with high detection accuracy.

-

Non-contacting type with no damage to moving parts.

-

High sealing performance under high pressure or vacuum condition.

Full welding float type with stainless steel guide pipe suitable for the toxic or explosion fluids that must not be leak outside from tank. -

Possible to measure not only interface between overlying and underlying fluids but also interface of upper or lower in emulsion layer generating in between.

-

A small moving probe inserted in the pipe has no electric parts. Maximum allowable temperature can be allowable temperature of its material.

-

Less failure with non-contact circuit.

-

Fail safe design that the probe is positioned at ZERO or FULL SCALE when level transmitter fails to detect the interface of object.

| Measurement range | Min. range 0~500mm , Max. range 0~10m (Any other range are possible) (Contact us for resetting after installation) |

| Measurement accuracy | 0.5%±1mm (Standard solution) |

| Output signal | DC4~20mA DC1~5V ※ One of the above signal |

| Input power | Model NQC-10: AC105V/210V 50/60HZ or DC24V Model NSC-10: AC105V/210V 50/60HZ Model NQC-V: AC105V/210V 50/60HZ or DC24V Model NQC-F: AC105V/210V 50/60HZ or DC24V |

| Power consumption | 50W |

| Linearity | 0.5% or less |

| Velocity response | 2500mm/min |

| Insulation | DC500V 50MΩ or over (Between input, power source and output) |

| Allowable temperature | Detector: -25℃~+200℃ (Depends on the specifications) Power source: Model PS-5: -10℃~+50℃ Power source: Model PS-9: -10℃~+50℃ |

| Allowable pressure | Detector: 2MPa (approx. 20.4kg/cm2G) (Depends on the specifications) |

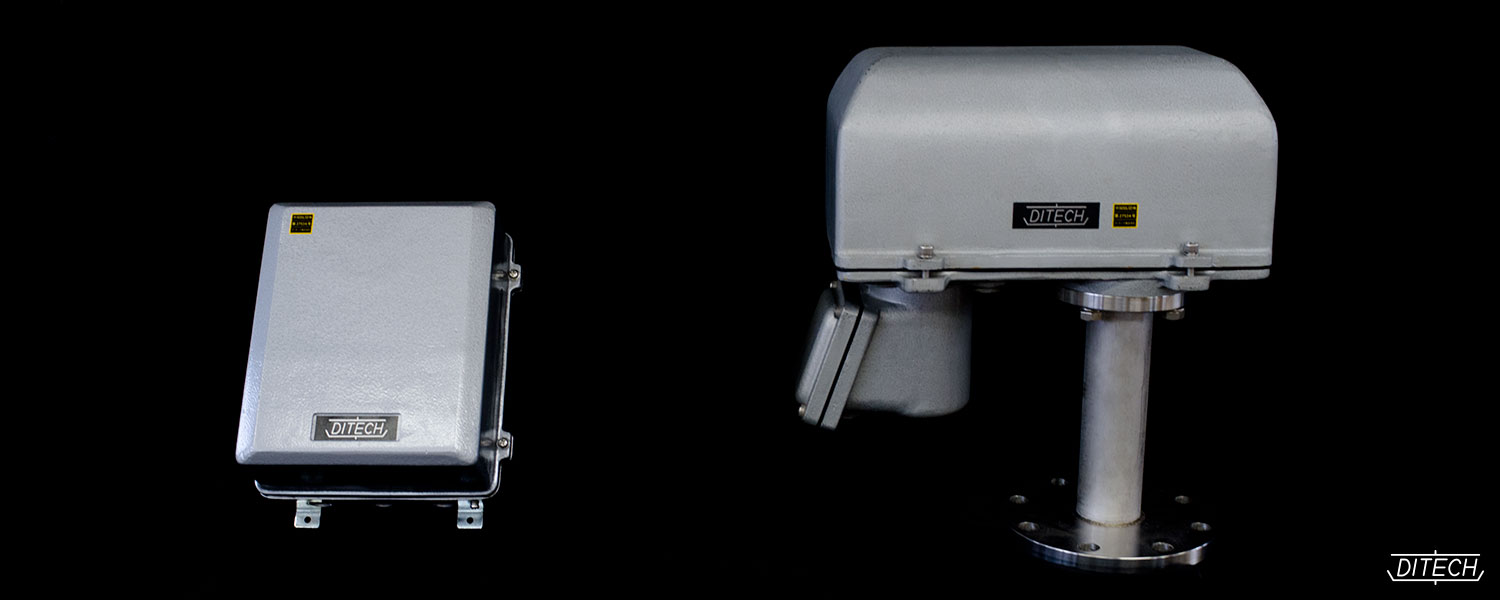

| Weight | Detector: Model MT-4: 23.7kg Power source: Model PS-5: 7.6kg Power source: Model PS-9: 10.4kg |

| Size | Detector: Model MT-4: 233(W)×380(D)×450(H) Power source: Model PS-5: 250(W)×145(D)×275(H) Power source: Model PS-9: 256(W)×150(D)×310(H) (mm) |

| Installation | Detector: Flange mounting, etc. |

| Material | Detector: Polycarbonate PTFE PVC FRP Pyrex Alumina, etc. Head case: Light alloy Salt resistant paint case, etc. |

DITECH,LTD.

DITECH,LTD.