Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

Vibrating Densitometer

QBS-D

NSB-D

proof

construction

Non-explosion-proof

Intrinsically safe construction(i3nG5)

to be

measured

Liquid concentration

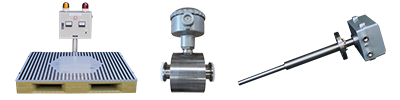

In a host of industrial fields, concentration monitoring for the purpose of production-line automation is a vital requirement for more cost-effective and labor-efficient control over processing operations. The vibrating densitometer is designed to continuously measure the concentration of fluids on line and automatically make available a record of the measurement situation via signal output. This densitometer is suitable for a broad range of applications, including online measurement of concentrations in drug or drinking water manufacturing tanks, and when installed at the rear of a shield boring machine, real-time monitoring of the concentration of excavated soil.

Vibrating viscometer is also available.

principles

The vibrating densitometer determines concentration according to the correlation between viscosity and concentration by allowing a vibrating blade to vibrate in a liquid and measure the resultant viscous drag. Since the instrument’s drive and detection mechanisms are completely non-contacting, the instrument is free of hysteresis and accurately detects even minimal changes in concentration.

-

Measures the fluids from cryogenic temperature (-200℃) to high temperature (600℃)

(Depends of the specifications) -

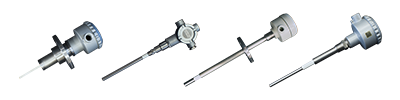

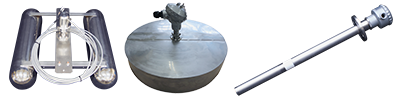

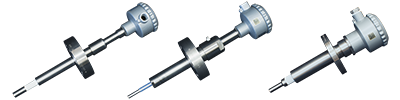

The dimensions of the device are flexibly adjustable to allow the most appropriate installation for any site.

-

The sensor consists of a welded single-body structure without a sealed section, so it features excellent air tightness and can be used even under high-vacuum conditions.

-

A choice of sensor liquid-contact section materials are available including corrosion-resistant titanium, hastelloy, Teflon coating, etc.

-

The drive section and detector section do not have to be installed on the process side of the vibrating probe and the shaft can also be extended, so the device possesses high-structural flexibility as well as good heat, corrosion and shock resistance.

-

The drive system employs DITECH's original magnetic bias system consisting of a non-sliding structure with a rotating shaft, etc. This design ensures a very long working life by greatly reducing abrasion and fatigue during operation.

-

The simplified structure is relatively unaffected by external interference, giving the device excellent durability and realizing maintenance-free operation.

-

A simplified structure ensures excellent cost competitively compared with rival models and eliminates running costs.

| Measurement range | 0~100% |

| Output signal | DC4~20mA DC1~5V ※ One of the above signal |

| Input power | Model QBS-D (Model PS-0D): AC105V/210V 50/60Hz or DC24V Model NSB-D (Model PS-25): AC105V/210V 50/60Hz |

| Power consumption | 10W |

| Allowable temperature | Detector: -200℃~600℃ (Depends on the specifications) Transducer: Model PS-0D: -10℃~+50℃ Transducer: Model PS-25: -10℃~+50℃ Special cable: Model RG (standard type): -10℃~+60℃ Special cable: Model TEF (heat resistance use): -200℃~+260℃ |

| Allowable load | Detector: According to user's specifications. |

| Allowable pressure | Detector: 5MPa (approx. 51kg/cm2G) |

| Weight | Transducer: Model PS-0D: 6.5kg Transducer: Model PS-25: 2.7kg |

| Size | Transducer: Model PS-0D: 216(W)×125(D)×259(H) Transducer: Model PS-25: 99(W)×130(D)×235(H) (mm) |

| Installation | Detector: Flange mounting Screws mounting Ferrule IDF, etc. |

| Material | Detector: SUS304 SUS316 Hastelloy Titanium, etc. Lining: PTFE Rubber, etc. Head case: Light alloy SUS304 Salt resistant paint case, etc. |

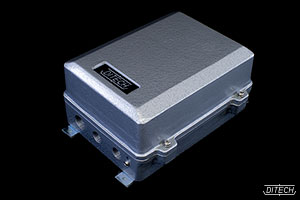

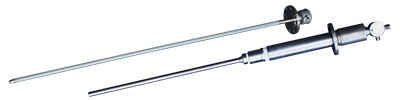

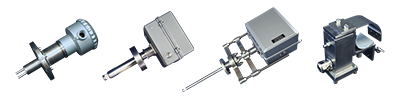

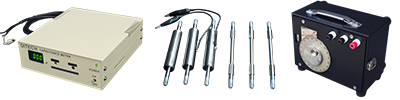

Model QBS-D

(Non-explosion-proof type)

<Separated transducer type>

This model is composed of detector unit, transducer and special cable.

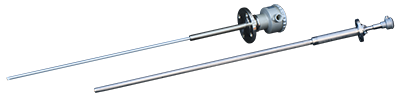

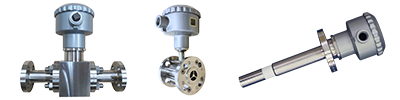

Model NSB-D

(Intrinsically safe construction / i3nG5)

<Separated transducer type>

This model is composed of detector unit, transducer and special cable.

DITECH,LTD.

DITECH,LTD.