Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

Level transmitter

for molten metals

DIM

system

Electromagnetic induction-type

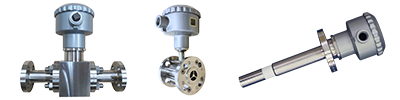

This level transmitter for molten metals are also designed to be suitable for a closed tank.

measured

molten metals |

|

|

At ultrahigh temperatures, conventional capacitive level transmitters cannot measure the level of good conductors. DITECH’s proprietary level transmitter for molten metals has been developed to make this possible.

The industrial sector is expecting market prices of metallic resources to soar in the future. Accordingly, metallic resources must be utilized efficiently. By carefully controlling the level of molten metal in metal refineries that consume huge amounts of energy, it becomes possible to cut wasteful use of energy and costs, as well as to reduce environmental burdens.

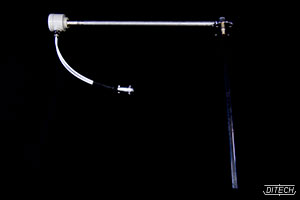

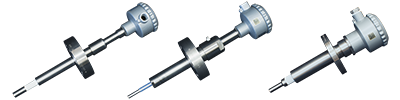

This device offers a simple sensor structure for an increased degree of design freedom that enables to integrate the protective tube into a closed vessel not to directly make contact with the outside air. In addition, it can detect the metal surface level without any influence of slag. Level switches for molten metals are also available.

principles

-

Suitable for a closed tank.

-

Possible to measure the surface level continuously.

-

Simple sensor structure for an increased degree of design freedom.

-

Wide range measurement from 10 mm to 2,000 mm.

measured

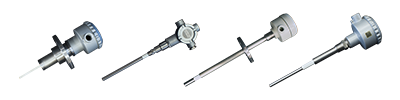

Use of various kinds of protective tubes suitable for the molten metal makes the device usable at high temperatures up to 2000 ℃.

| Object to be measured |

Melting points |

|

|---|---|---|

| Mercury |  |

-38.9℃ |

| Cesium |  |

29℃ |

| Sodium |  |

98℃ |

| Lithium |  |

179℃ |

| Tin |  |

232℃ |

| Bismuth |  |

271℃ |

| Cadmium |  |

321℃ |

| Lead |  |

328℃ |

| Zinc |  |

419℃ |

| Magnesium |  |

651℃ |

| Aluminum |  |

660℃ |

| Object to be measured |

Melting points |

|

|---|---|---|

| Barium |  |

717℃ |

| Calcium |  |

810℃ |

| Germanium |  |

959℃ |

| Gold |  |

1063℃ |

| Copper |  |

1083℃ |

| Manganese |  |

1244℃ |

| Silicon |  |

1410℃ |

| Nickel |  |

1455℃ |

| Iron |  |

1539℃ |

| Titanium |  |

1727℃ |

| Platinum |  |

1774℃ |

| Measurement range | 10mm~2000mm (The maximum operating temperature depends on the materials of the protective tube.) |

| Output signal | DC4~20mA DC1~5V ※ One of the above signal |

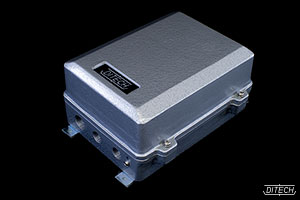

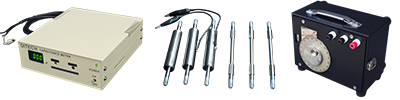

| Input power | Model DIM (Model PS-17): AC105V/210V 50/60Hz or DC24V |

| Power consumption | 50W |

| Linearity | ±2% |

| Accuracy | Within ±2% (When adhesion is intense: within ±5%) |

| Allowable temperature | Detector: -60℃~+2000℃ (Depends on the specifications) Transducer: Model PS-17: -10℃~+50℃ Special cable: Model DSC-17: -10℃~+60℃ Special dedicated heat resistant cable: (Depends on the specifications) |

| Allowable pressure | Detector: 30MPa (approx. 306kg/cm2G) (Depends on the specifications) |

| Weight | Transducer: Model PS-17: 5.5kg |

| Size | Transducer: Model PS-17: 216(W)×125(D)×259(H) (mm) |

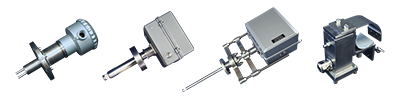

| Installation | Detector: Flange mounting Screws mounting, etc. |

| Material | Detector: SUS304 SUS310S SUS316 SUS316L Tungsten Ceramic Molybdenum, etc. Head case: Light alloy Silver SUS304, etc. |

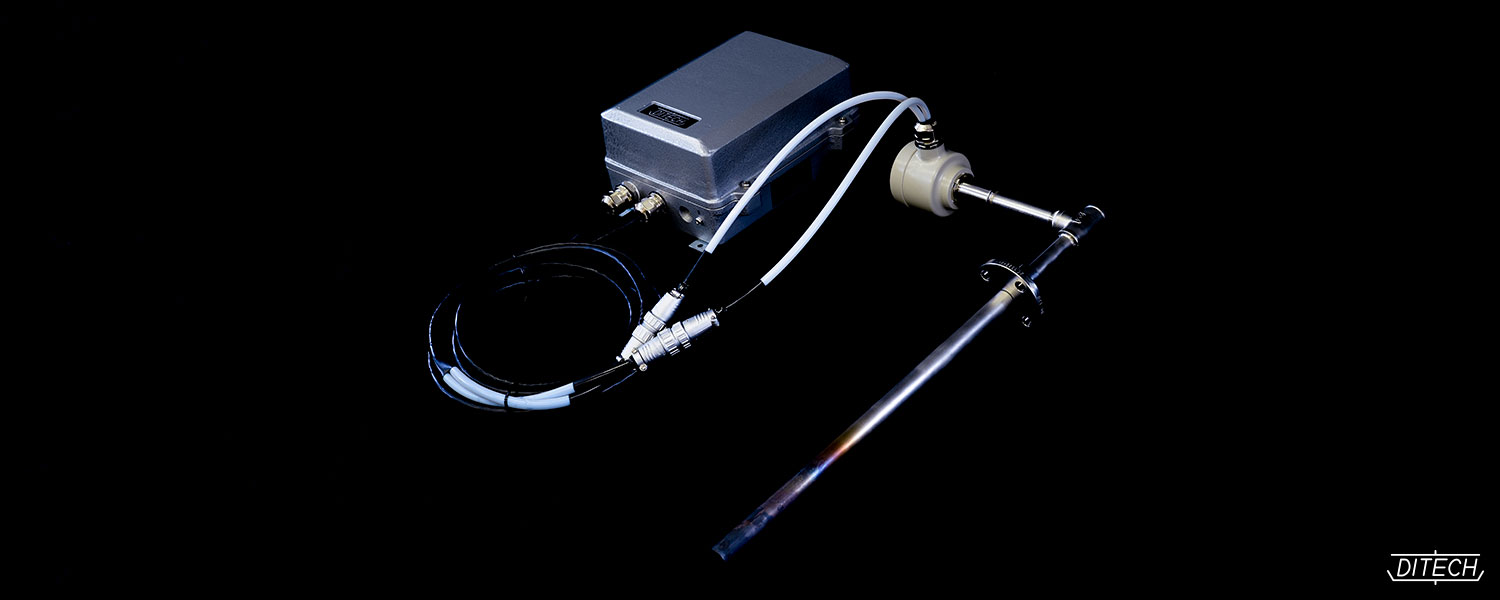

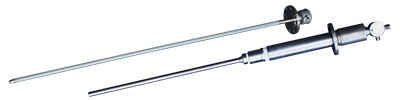

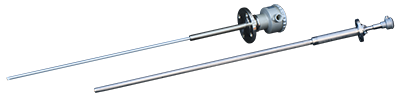

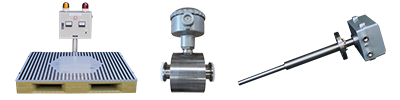

Model DIM

(Non-explosion-proof type)

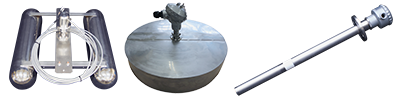

<Totally separated transducer type>

This model is composed of detector unit, transducer and 2 special cables that are 3 core control cable.

DITECH,LTD.

DITECH,LTD.