Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

Buildup meter and

Densitometer

QBS-CT

This level transmitter for molten metals are also designed to be suitable for a closed tank.

measured

<Buildup meter>

Thickness of powder buildup on a vessel wall

<Densitometer>

Density of powder moving in a vessel

The buildup meter/densitometer is designed to measure, in a powder manufacturing process, both the thickness of the buildup of a powder on the wall of a vessel in which the powder moves around and changes in the density of the moving powder in the vessel.

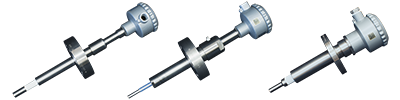

Incorporating DITECH’s proprietary capacitance-compensating (guard) system, the buildup meter covers a range within 10 mm from the wall surface (detector surface), while the densitometer, being independent of any powder buildup on the probe, measures the density of a distant part of the powder.

Since one detector unit is shared and performs two types of measurement for different purposes, two types of switch-selectable transducer are provided for intrinsic-safety reasons. The use of one detector unit for two types of measurement translates to advantages such as installation in a limited space, simple maintenance and low cost.

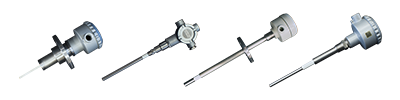

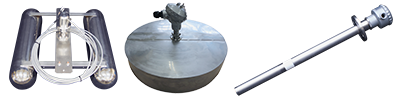

The detector has a double-concentrically arranged flat probe, in which the main disk-shaped probe is at the center, a ring probe is around the main probe, and, when installed, the inner wall of the vessel serves as an outer probe.

principles

The device incorporates a ground-guard system, with which the measurement range is limited to a zone approximately 10 mm from the detector surface and the detector is immune to the influences of the powder outside this zone. Capacitances between the two probe electrodes and the ground (vessel wall) occur between each probe and the input resistance. If the impedances of these elements are able to be ignored, these capacitances are cancelled and only the capacitance that occurs between the two electrodes is picked up as a detection signal.

The capacitance between the probe and the ground is measured in order to determine the density of the powder sufficiently away from the detector surface independently of the buildup on the detector surface. Consequently, a compensating probe (guard probe) is provided between the main probe and the vessel wall. Capacitance in the proximity of the detector surface is canceled by the guard effects. Capacitance sufficiently away from the detector surface becomes dominant as the detector signal.

| Measurement system | Capacitance-compensating type (guard type) |

| Output signal | DC4~20mA DC1~5V ※One of the above signal |

| Input power | Model QBS-CT (Model PS-0C): AC105V/210V 50/60Hz or DC24V Model QBS-CT (Model PS-0T): AC105V/210V 50/60Hz or DC24V |

| Power consumption | 20W |

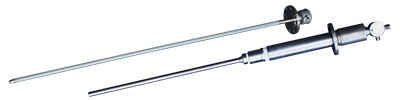

| Allowable temperature | Detector: -200℃~+1000℃ (Depends on the specifications) Transducer: Model PS-0C: -10℃~+50℃ Transducer: Model PS-0T: -10℃~+50℃ Special cable: Model DSC-15 (high accuracy use): -10℃~+60℃ Special cable: Model DSC-05 (small size): -10℃~+60℃ Special cable: Model DSC-13 (heat resistance use): -50℃~+200℃ |

| Allowable pressure | Detector: 2MPa (approx. 20.4kg/cm2G) (Depends on the specifications) |

| Weight | Transducer: Model PS-0C: 5.5kg Transducer: Model PS-0T: 5.5kg |

| Size | Transducer: Model PS-0C: 216(W)×125(D)×259(H) Transducer: Model PS-0T: 216(W)×125(D)×259(H) (mm) |

| Surface treatment | Detector: Buff Electrolytic polishing, etc. |

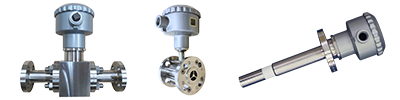

| Installation | Detector: Flange mounting Screws mounting Ferrule IDF, etc. |

| Material | Detector: SUS304 SUS316 SUS316L Hastelloy Titanium Tantalum Nickel PTFE Ceramic, etc. Lining: PTFE Glass Rubber, etc. Head case: Light alloy SUS304 Salt resistant paint case, etc. |

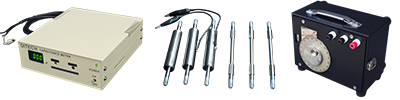

Model QBS-CT

(Non-explosion-proof type)

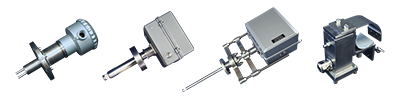

<Separated transducer type>

This model is composed of detector unit, transducer and special cable.

DITECH,LTD.

DITECH,LTD.