Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

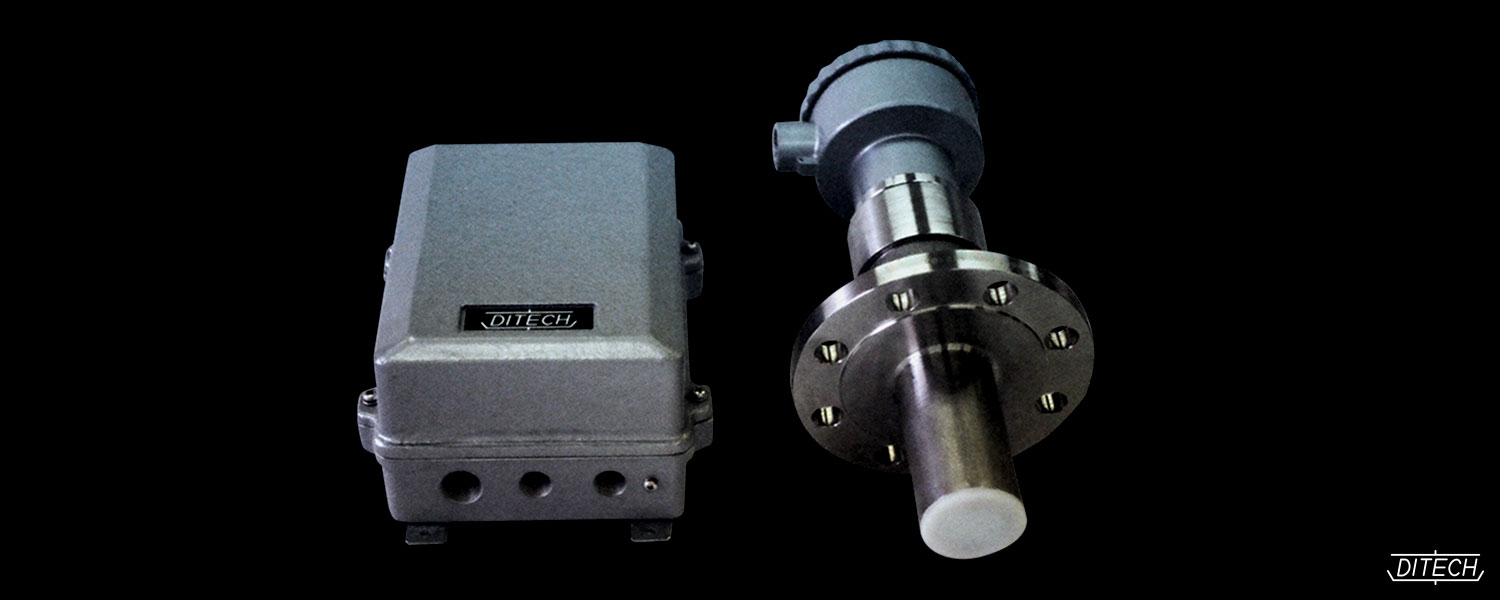

Microwave-based

flowing-powder detector

D-MM3

to be

measured

Powders flowing in a container, tank or silo

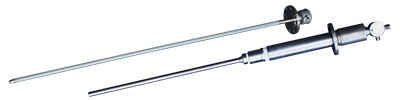

This device is designed to detect, in a manufacturing process, powder flowing in a tank. It can be used in a broad range of applications with its setting capability ranging from minimal to large amounts. The microwave-based flowing-powder detector is free from the need to protrude in the tank since its sensor is designed to have a flat face.

principles

With the Doppler effect applied in it, this instrument is designed to detect the microwave that is reflected or absorbed by the powder and/or granular material through which the microwave radiated at the point of measurement can pass.

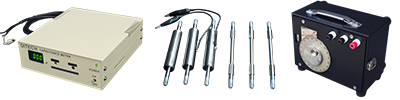

The device to radiate the microwave and the wave detector are both built in this detector. The detector extracts, from the microwave, a signal proportional to the peak value of the microwave and outputs it as a contact point signal. The sensitivity of the detector is directional, peaking in the axial direction and decreasing in directions deviating from the axial.

| Output signal | 1 transfer contact point AC250V 5A |

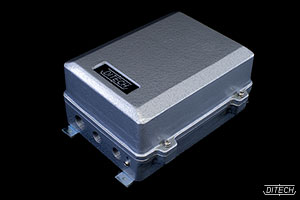

| Input power | Model D-MM3 (Model PS-6): AC105V/210V 50/60Hz or DC24V |

| Power consumption | 5W |

| Allowable temperature | Detector: Depends on the specifications Transducer: Model PS-6: -10~+50℃ Special cable: Model DSC-15 (high accuracy use): -10℃~+60℃ |

| Allowable load | Depends on the specifications |

| Allowable pressure | Depends on the specifications |

| Weight | Transducer: Model PS-6: 5.5kg |

| Size | Transducer: Model PS-6: 216(W)×125(D)×259(H) (mm) |

| Installation | Detector : Flange mounting, etc. |

| Material | Detector: SUS04 SUS316 PTFE, etc. Head case: Light alloy SUS304 Salt resistant paint case, etc. |

DITECH,LTD.

DITECH,LTD.