Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

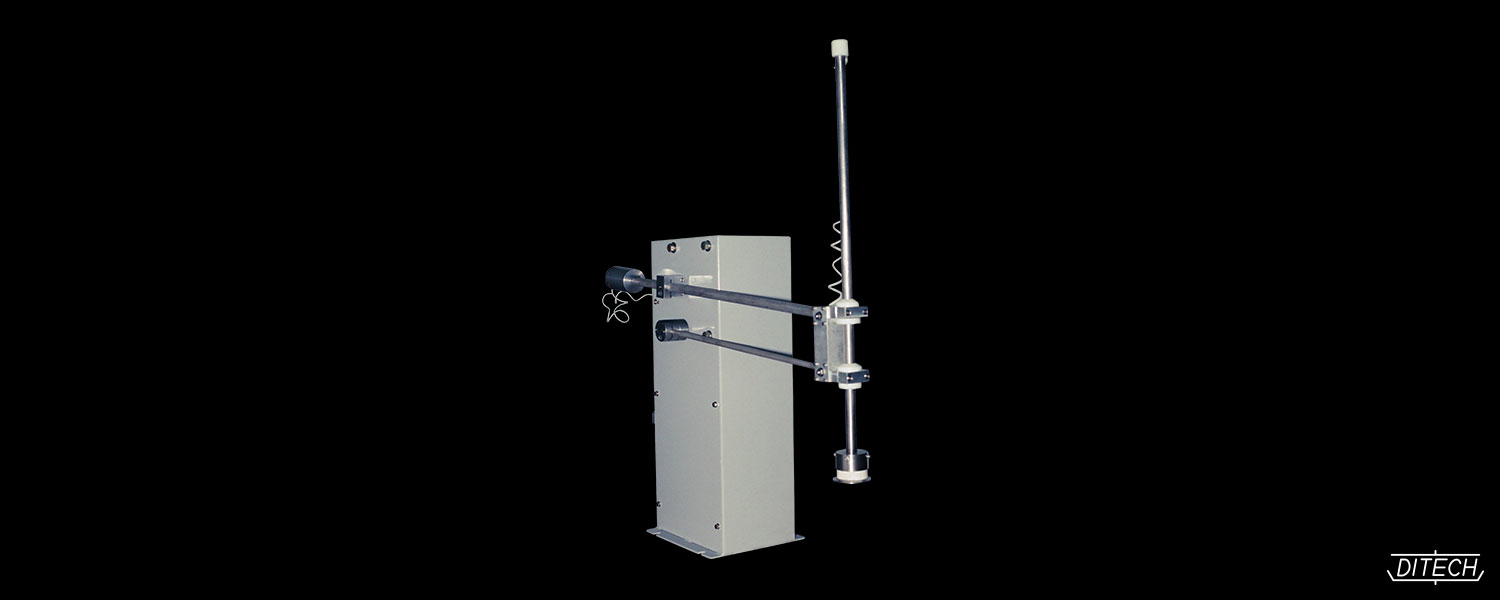

Non-contact self-balancing

Level transmitter

DNC

This level transmitter is designed to carry out non-contact measurement of object to be measured.

This device incorporates a capacitive sensor and a self-balancing mechanism to carry out non-contact measurement of the object to be measured. The non-contact self-balancing level transmitter is suitable for various objects placed in an open vessel (tank), such as all kinds of liquid, including molten metal, and measures the height of blocks produced in a product molding process. To use this level transmitter in a closed vessel (tank), please consult us.

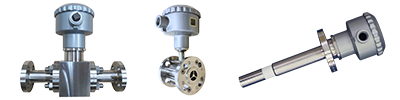

For a closed vessel (tank), the level transmitter for molten metals and the self-balancing interface level transmitter are also available.

-

Self-balancing level transmitter with high detection accuracy.

-

Non-contact level transmitter free of buildup of the object being measured to achieve stable performance.

-

Hygienically clean operation since the device does not come into contact with the object being measured.

(liquids)

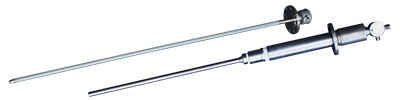

The sensor follows changes of the liquid level while maintaining its position constantly 20 mm to 50 mm away from the liquid level. The changing sensor location is detected with a potentiometer and transmitted as a level signal output.

(moldings)

-

The sensor is lifted and on standby.

-

Upon receiving a contact point output signal (ON) from the user’s manufacturing system after the molding is extruded and positioned on the bed, the sensor begins to measure.

(Required time: approx. 3 s; Variable range: 0.5 to 5 s) -

When the sensor undergoes a self-balancing step and then stops, the deviation is sampled.

(Required time: approx. 1 s; Variable range: 0.5 to 5 s) -

After the sampling step, the sensor is lifted at maximum speed. When lifting is completed, a contact point signal is output.

(Required time: approx. 2 s; Overall time: approx. 6 s) -

The sensor returns to the state described in 1.

(maintenance)

For maintenance work, setting the selector switch on the main assembly to TEST allows the probe be lifted to standby position and stop. For measurement, setting the selector switch to MEASU lowers the probe to follow the liquid level, with a certain distance maintained between the liquid level and the probe.

| Measurement system | Capacitive system + Non-contact self-balancing system |

| Measurement range | According to user's specifications |

| Output signal | DC4~20mA DC1~5V ※ One of the above signal |

| Input power | AC105V/210V 50/60Hz or DC24V |

| Power consumption | 35W |

| Allowable temperature | Detector: According to user's specifications Power box: Model PS-14: 0℃~+50℃ Digital indicator: 0℃~+50℃ Special cable (heat resistance use): Depends on the specifications. |

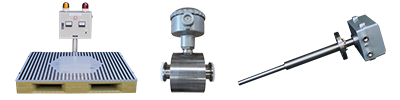

| Installation | Detector: Anchor bolt mounting to the floor, etc. |

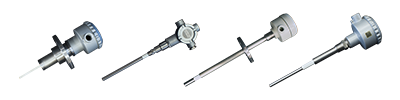

| Material | Detector: SUS304 SUS316, etc. |

Model DNC

(Non-explosion-proof type)

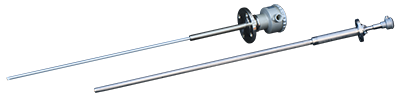

<Detector with built-in transducer type>

This model is composed of detector with built-in transducer and power box.

DITECH,LTD.

DITECH,LTD.