Manufacturer of Level Switch, Level Transmitter,

Detector and Sensor DITECH,LTD.

Level transmitter

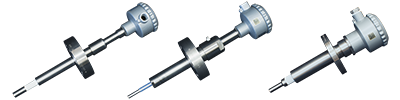

for vertical piping

QBS-VP

NSB-VP

proof

construction

Non-explosion-proof

Intrinsically safe construction(i3nG5)

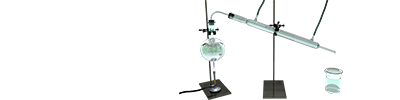

These level switches are optimal for measuring the amount of raw material.

The level transmitter for vertical piping is installed on vertical piping. Its typical installation locations are below a raw material charging port, immediately above an extruder and tank-to-tank vertical piping.

Continuous measurement and control of the object being measured stabilizes product quality and reduces material loss.

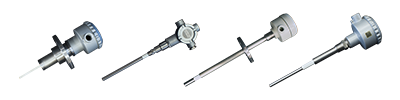

Small- and large-diameter level transmitters are available to cover various piping geometries. The detector is free from the need to protrude in the piping and it does not obstruct the flow.

principles

Every material has intrinsic electrical characteristics such as permittivity and conductivity. The in-pipeline stationary detector is installed below a raw material charging port or between pipes. It detects capacitance that changes with increases or decreases of the object being measured and converts the detected capacitance into a standardized signal.

| Measurement system | Capacitance system |

| Measurement range | Min. range 0~50mm , Max. range 0~500mm (Any other range are possible) |

| Output signal | DC4~20mA DC1~5V ※ One of the above signal |

| Input power | Model QBS-VP (Model PS-0VP): AC105V/210V 50/60Hz or DC24V Model NSB-VP (Model PS-2): AC105V/210V 50/60Hz |

| Power consumption | 10W |

| Allowable temperature | Detector: -25℃~+70℃ (Depends on the specifications) Transducer: Model PS-0VP: -10℃~+50℃ Transducer: Model TR-2VP: -25℃~+70℃ Power source: Model PS-2: -10℃~+50℃ Special cable: Model DSC-15 (high accuracy use): -10℃~+60℃ Special cable: Model DSC-05 (small size): -10℃~+60℃ Special cable: Model DSC-13 (heat resistance use): -50℃~+200℃ |

| Allowable pressure | Detector: 20Mpa (approx. 204kg/cm2G) (Depends on the specifications) |

| Weight | Transducer: Model PS-0VP: 5.5kg Transducer: Model TR-2VP: 4.3kg Power source: Model PS-2: 7.6kg |

| Size | Transducer: Model PS-0VP: 216(W)×125(D)×259(H) Transducer: Model TR-2VP: 200(W)×149(D)×220(H) Power source: Model PS-2: 250(W)×145(D)×275(H) (mm) |

| Surface treatment | Detector: Inner surface polishing, etc. |

| Installation | Detector: Flange mounting, etc. |

| Material | Detector: SUS304 SUS316 PTFE Alumina Quartz glass, etc. Lining: PTFE Glass Rubber, etc. Head case: Light alloy SUS304 Salt resistant paint case, etc. |

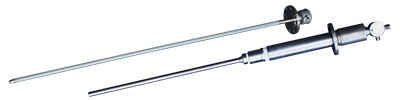

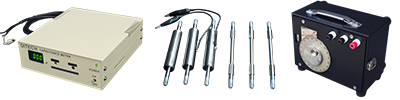

Model QBS-VP

(Non-explosion-proof type)

<Separated transducer type>

This model is composed of in-pipeline detector unit, transducer and special cable.

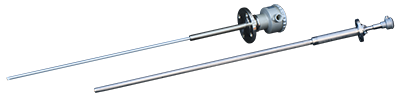

Model NSB-VP

(Intrinsically safe construction / i3nG5)

<Totally separated detector unit type>

This model is composed of in-pipeline detector unit, transducer, relay power source and special cable that is 4 core control cable. As the transducer is designed to be installed in a dangerous area, the special cable can be made short enough to minimize picked-up noises, thus permitting a stable performance to be obtainable. As to performance, this model has the same characteristics as those of Model QBS-VP.

DITECH,LTD.

DITECH,LTD.